Reversible Crosslinking for Sustainable Reinforced Composites

Researchers have developed Covalent Adaptable Networks (CANs) for Carbon Nanotube reinforcement. These networks feature chemically reversible crosslinks, making them an option for producing recyclable thermosets.

Researchers demonstrated how covalent adaptable networks can be significantly strengthened using single-walled carbon nanotubes (SWNTs), particularly in their mechanically interlocked form.

You can also read: Closing the Carbon Fiber Loop

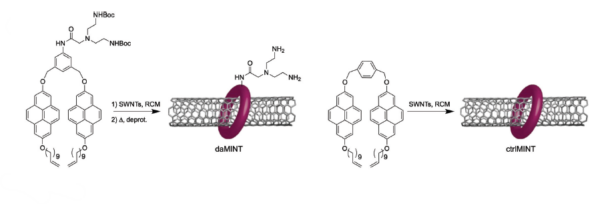

Researchers have explored reinforcing the Covalent Adaptable Networks (CANs) with single-walled carbon nanotubes (SWNTs) to enhance their performance. SWNTs, known for their strength-to-weight ratio, are ideal fillers for polymers, but achieving efficient load transfer remains challenging. Therefore, introducing SWNTs in their mechanically interlocked form (MINTs) provides a promising alternative.

Addressing the Reinforcement Challenge

In conventional SWNT composites, issues with dispersion and bonding often limit their mechanical performance, falling short of predictions. However, mechanically interlocked nanotubes (MINTs) offer a solution by enhancing the interaction between SWNTs and the polymer matrix. These MINTs significantly improve the dispersion of nanotubes and optimize load transfer, resulting in superior composite properties. By integrating MINTs into polyimine (PI) CANs, researchers achieved remarkable mechanical strength and stiffness improvements. Thus, MINTs represent a significant advancement in composite reinforcement.

Simplified chemical structure from carbin nanotubes with reversible crosslinking method. Courtesy of Reinforcement of Polyimine Covalent Adaptable Networks with Mechanically Interlocked SWNTs derivatives of SWNTs.

Enhanced Performance of MINT-Reinforced Composites

The study demonstrated that MINT-reinforced PI Covalent Adaptable Networks (CANs) showed a 77% improvement in stiffness and a 100% increase in tensile strength. These results highlight the efficient load transfer from the polymer matrix to the nanotubes, overcoming limitations in traditional composites. Moreover, using MINTs allows for optimal utilization of SWNTs’ mechanical properties. Consequently, this breakthrough underscores the potential of MINTs to revolutionize the strength of polymer composites.

Recyclability Without Compromising Strength

Another key advantage of MINT-reinforced PI Covalent Adaptable Networks (CANs) is their recyclability, achievable through chemical and thermal processes. Unlike traditional thermosets, these composites maintain their mechanical properties even after multiple recycling cycles. This makes them highly suitable for sustainable applications, where performance and recyclability are essential. Therefore, the recyclability of MINT-reinforced composites enhances their environmental appeal and practical utility.

Sustainable Carbon Fiber Composites

Furthermore, the study explored the application of MINT-reinforced composites in carbon fiber laminates, which yielded impressive results. The carbon fiber composites showed a 66% increase in stiffness and a 73% improvement in tensile strength. These enhancements demonstrate the potential of MINT-reinforced CANs to replace conventional materials in industries requiring high-performance and recyclable composites.

By integrating MINTs into CANs, researchers have created high-performance composites that combine strength and recyclability. This innovation provides a sustainable solution for industries seeking to reduce plastic waste while maintaining material performance.