Modifying the Slip of Plastic Films with Additives

Plastic film’s slip and friction characteristics are essential for optimal performance in flexible packaging. Modifying these characteristics with additives can greatly benefit manufacturers.

The slip and friction of plastic films are essential properties that help achieve adequate functionality in flexible packaging.

The COF and blocking force affect material flow, package opening, and stack stability. These are critical factors in the converting, filling, storage, transportation, and distribution.

Here is a summary of the main additives available on the market to modify plastic films’ COF and blocking force.

You can also read: Essential Additives for Plastic Modification.

Slip Additives

These additives lower the COF (Coefficient of Friction) by modifying the films’ surface. A low COF is indispensable for proper material flow over converting and packaging machines’ rollers and metal surfaces (FFS machines).

Although there is no consensus on COF levels, in practice the following values are usually taken as reference:

| Low COF | ≤0.20 |

| Medium COF | 0.20-0.40 |

| High COF | >0.40 |

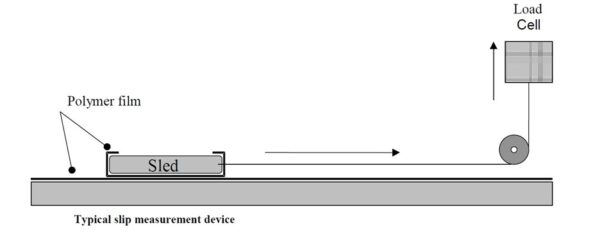

A typical slip measurement device for plastic films. Courtesy of The effect of polyolefin formulation and processing variables on slip agent performance.

The film’s external surface usually has a slightly higher COF than the inside (sealing), generating a higher level of friction.

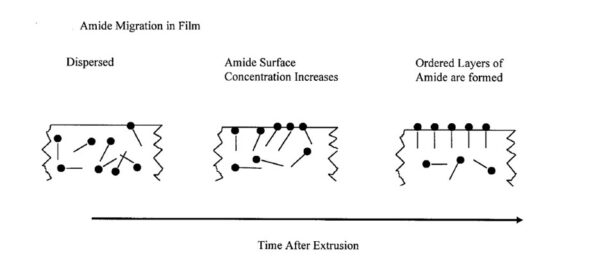

The most used slip additives are based on fatty acid amides, such as erucamide, which migrate to the surface, forming an oily layer that reduces friction. These additives have an excellent cost-benefit balance; however, the speed and direction of migration are quite variable. Resins without slip additives produce high COF levels, but most applications require a low COF on the inner sealing layer and a high COF on the outer side. Manufacturers use slip additives to achieve this balance.

Amide migration steps in extruded plastic film. Courtesy of The effect of film winding tension and melt temperature on COF and others properties of PE blown film.

More Options for Sticky Resins

For more demanding packaging applications, higher molecular weight amides are available, which have a more controlled migration speed. For this reason, they are more stable to variables such as temperature, time, roll tension, and the presence of polar substrates in the structure.

Additionally, there are non-migratory slip additives, which allow obtaining an instantaneous and permanent low COF. These are especially useful for very thin films or applications that require distinct slip levels between the internal and external surfaces. As in migrating additives, the films do not require conditioning time to reach equilibrium.

Some key aspects for slip additive performance are the level of COF needed on the external and internal surface, total film thickness, distribution of layers in the coextrusion, and packaging structure. Also, the presence of polar substrates (PET, EVOH, Polyamide, adhesives) and very sticky resins such as plastomers should be considered, as should the variation over time and ambient temperature.

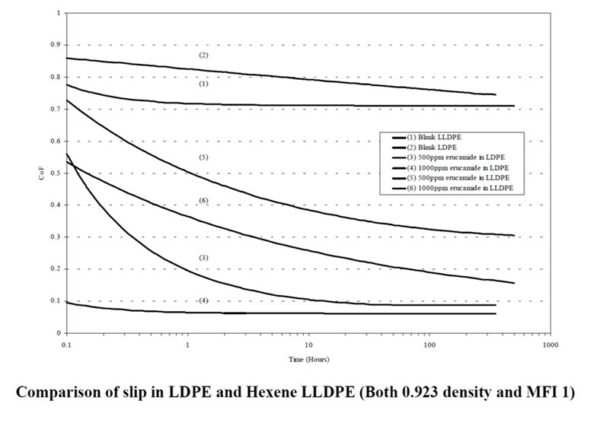

This graph compares the COF vs time of LDPE and LLDPE with 500 and 1000 ppm of erucamide. The effect of polyolefin formulation and processing variables on slip agent performance. Courtesy of The effect of polyolefin formulation and processing variables on slip agent performance.

Antiblock Additives

Plastic films usually have smooth surfaces, which means they tend to stick together when they come into contact, making it difficult to separate them. This phenomenon is called blocking, making it difficult to open the package or bag during the filling process or even for the end consumer.

Blocking is the adhesion of two adjacent layers of film. This problem is more noticeable in polyethylene and polypropylene films (blown or cast) and is caused by Van der Waals forces between the polymer’s amorphous regions.

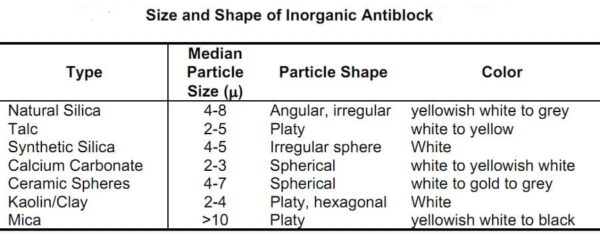

An effective method for combating these issues is to add an anti-block additive. The most common ones use minerals of fine particle size. These produce micro-roughness on the surface that allows air to enter between the films in contact, easing their separation. It is important to note that anti-blocks are not migratory, and only the particles that protrude from the film surface contribute to their functionality.

Size and shape of main inorganic anti-block. Courtesy of Ampacet Corporation.

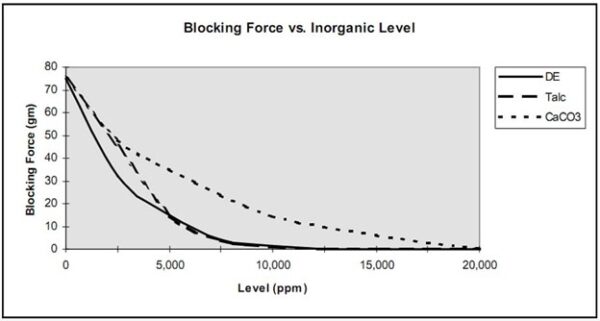

Some commonly used anti-blocking compounds are talc, natural silica, and synthetic silica. Natural silica (or diatomaceous earth/DE) and talc are the most efficient anti-blocking compounds, given their irregular shapes.

Organic Antiblocking Compounds

There are also organic antiblocking compounds that can function as slip additives.

This graph compares blocking force of mineral antiblock vs level in ppm. Courtesy of Ampacet Corporation.

Slip and anti-blocking additives have a synergistic effect, so they are typically used together to achieve the best packaging performance.

Most of the polyethylene resins used in film extrusion for flexible packaging contain slip and anti-blocking additives. However, evaluating the need to use masterbatch additives to achieve the best packaging performance is crucial.

Anti-slip Additives

Certain applications require stacking packages during storage, transport, or display, so manufacturers increase the outer layer’s COF using anti-slip additives. These can increase the stickiness of the surface (smooth finish anti-slip) or produce roughness. Usually, the goal is to achieve a static COF greater than 0.45. It is important to note that using resins with migratory slip additives interferes with the anti-slip effect, generating an antagonistic effect.

Resins without slip additives produce high COF levels, but most applications require a low COF on the inner sealing layer and a high COF on the outer side. Manufacturers use slip additives to achieve this balance.

In conclusion, smart use of slip, anti-slip, and anti-block additives is important for producing high-performance flexible packaging.