Machine Learning for Pyrolisis Optimization

Innovative technologies are optimizing the waste-to-energy process: saving plastic waste from landfills and turning it into valuable resources.

The waste-to-energy strategy offers a new life for plastic waste. This waste can be repurposed into valuable fuels and chemicals using incineration and pyrolysis. This process keeps plastics out of landfills, promoting sustainability and a circular economy. With recent technological advances, researchers hope to optimize this process for improved yield and efficiency. Machine learning (ML) processes offer an innovative approach to optimizing pyrolysis and fine-tuning plastic waste conversion.

You can also read: Unlocking Business Potential in the Plastic Recycling Market by 2030

Real-Time Pyrolysis Optimization

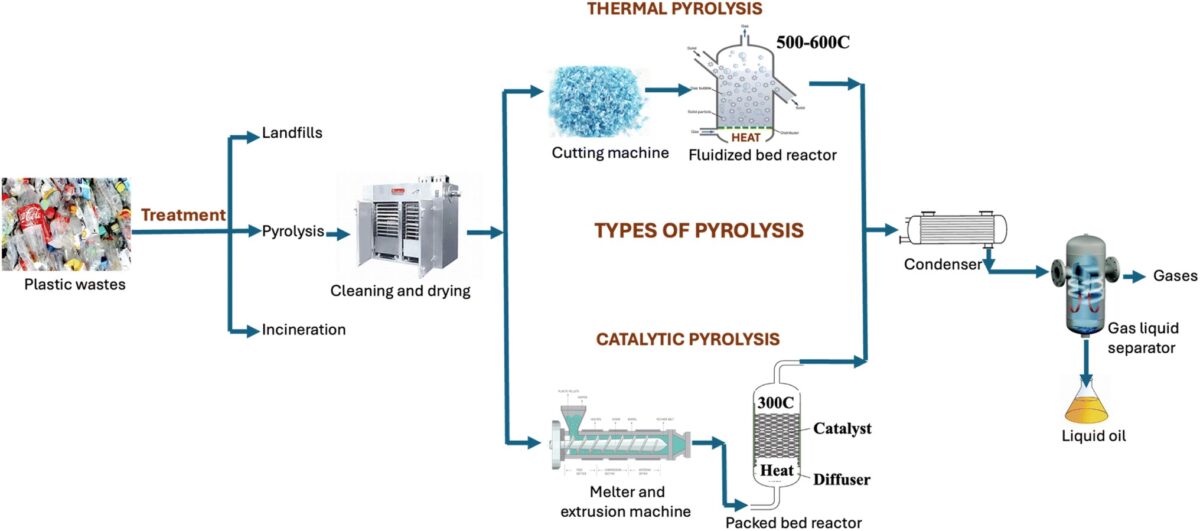

The pyrolysis process breaks lengthy polymer chains of plastic waste, transforming them into shorter-chain petrochemicals. Catalysts lower the energy requirements of this process, enhancing efficiency, product quality, and yield. Every material is different, and the type and purity of plastic waste impact pyrolysis parameters. When working with post-consumer waste, it is crucial to understand these factors to optimize the process.

The process of converting plastic waste to valuable end products using pyrolysis. Courtesy of Advances in plastic to fuel conversion: reactor design, operational optimization, and machine learning integration.

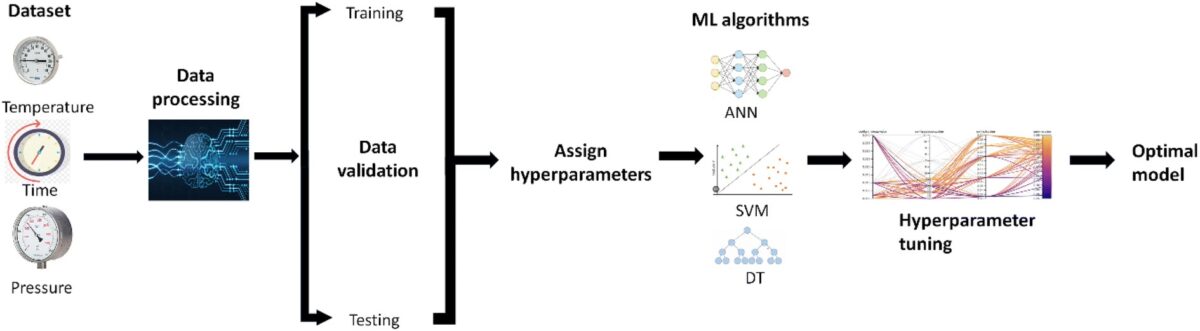

Because of the variety of post-consumer plastics, ML algorithms can be a powerful tool in pyrolysis optimization. Using historical data and sensor readings, ML algorithms forecast, analyze, and enhance pyrolysis product output. These algorithms can help adjust pyrolysis process parameters in real-time according to the requirements of the waste. This ability is extremely beneficial for process optimization, enhancing productivity, product quality, and efficiency, while also reducing costs.

ML learning models can help optimize the pyrolysis process for plastic waste. This flow chart shows the ML workflow for this use case. Courtesy of Advances in plastic to fuel conversion: reactor design, operational optimization, and machine learning integration.

Four Effective ML Methods

Various ML techniques have shown promise for plastic waste pyrolysis optimization. Researchers have widely used neural networks (NN) and support vector regression (SVR) for modeling this process. NN is capable of handling large data sets, making it a promising option for optimizing pyrolysis yield. Additionally, decision tree (DT) algorithms have performed well for forecasting liquid yield. Gaussian process (GP) models have demonstrated satisfactory performance for forecasting oil, char, and gas yield. Using gas-chromatography-mass spectrometry (GC/MS) in tandem with ML has shown success for predicting and analyzing liquid products.

Better Optimization, Better Outcomes

ML is a promising asset for plastic waste pyrolysis optimization because of its ability to optimize parameters in real-time. By continuing to explore these technologies, researchers ensure the effective reuse of plastic waste. Pyrolysis for plastic waste offers an alternative to finite fossil fuels, and optimization can bolster this initiative. Additionally, this process can reduce the environmental impact of post-consumer plastic. By promoting regenerative industrial systems, the waste-to-energy strategy can reduce both costs and greenhouse gas emissions.