With stricter regulations and growing sustainability commitments, demand for recycled plastics is rising, positioning advanced recycling companies as industry leaders. Courtesy of QuantaFuel.

The plastic recycling market thrives on the global push toward a circular economy. In 2023, only 8.2% of plastics worldwide came from post-consumer recycling. As governments enforce stricter regulations and businesses commit to sustainability, the demand for recycled plastics continues to rise. Companies that offer advanced recycling technologies or closed-loop systems are well-positioned to lead this transformation.

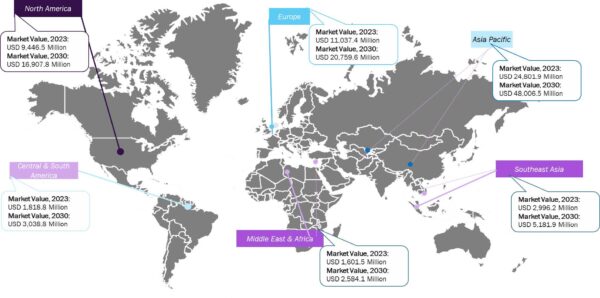

Figure 1. Recycled Plastics Market, by region, 2023 & 2030 (USD Million). Taken from: Plastics Recyclers Europe, NAPRA, Recycle Association, Company Annual Reports, Primary Interviews, Grand View Research.

You can also read: Additives in Action: Enhancing Plastic Recycling.

Recycled Plastics Market Size (USD Million). Taken from: Plastics Recyclers Europe, NAPRA, Recycle Association, Company Annual Reports, Primary Interviews, Grand View Research.

The recycled plastics market reached a valuation of USD 51.7 billion in 2023 and will grow at a compound annual growth rate (CAGR) of 9.5% from 2024 to 2030.

Polyethylene (PE) led the market, accounting for over 26% of the global revenue in 2023, due to its extensive use in packaging applications. The packaging sector itself commanded over 37% of the global market share. This is driven by the growing demand for sustainable food and beverage containers, personal care products, and industrial packaging.

On the other hand, plastic bottles emerged as the dominant source of recycled plastics, contributing over 74% of global revenue in 2023. Their broad applications across industries, including food, beverages, and pharmaceuticals, highlight their significance in the recycling landscape. Additionally, Industries will drive polypropylene’s growth at a CAGR of 10.2% by leveraging its superior mechanical and chemical properties.

The integration of chemical and mechanical recycling is revolutionizing the industry. Advanced chemical recycling technologies can process complex materials like multilayer films and flexible plastics, effectively complementing traditional mechanical recycling. A study led by Frost & Sullivan projects that the chemical recycling sector will grow at a compound annual growth rate (CAGR) of 43.5% from 2022 to 2030. By 2030, this sector will play a pivotal role in achieving ambitious sustainability goals, such as incorporating up to 50% recycled content in packaging by leading consumer goods companies.

Chemical recycling solutions break down plastics into their raw materials, enabling higher-quality outputs. Although chemically recycled plastics currently account for just 0.2% of European production, the growth potential is immense. As industries prioritize reducing their carbon footprint, this technology continues to expand.

Efficient collection, sorting, and processing of plastic waste remain critical challenges in the recycling ecosystem. Investments in infrastructure can provide long-term benefits for both companies and municipalities. Innovations such as MURA Technology’s HydroPRS sy

stem, which converts plastic waste into hydrocarbon feedstock in just 30 minutes, highlight the potential of advanced systems to close the loop on hard-to-recycle plastics.

Chemical recycling of plastic waste. Courtesy of Quanta Fuel.

Countries like Germany, Italy, and Spain are leading contributors to Europe’s recycled plastics production. Germany alone accounts for 22% of mechanically and chemically recycled plastics. Innovative companies like Quantafuel and Plastic Energy are driving advancements in chemical recycling. Quantafuel specializes in converting low-quality plastics into purified gas for chemical processing, while Plastic Energy’s patented process turns end-of-life plastics into clean recycled materials for industrial use. These breakthroughs are vital for scaling circular solutions globally.

ANTEC® 2025 research reveals critical insights about when and why carbon fiber reinforcement succeeds or…

At PET Technologies, women are not only challenging stereotypes. They're driving innovation and shaping the…

Polymer extrusion wastes a significant amount of energy on inefficiencies. Here is how modern technologies…

A new hydrophilic coating could give players an edge, enabling them to maintain control and…

As industries strive to integrate recycled materials into mainstream manufacturing, researchers continue to explore ways…

Companies worldwide are reevaluating their production processes. One major shift is the use of recycled…