Metal 3D Printing in Mold Making: A Technologies Comparison

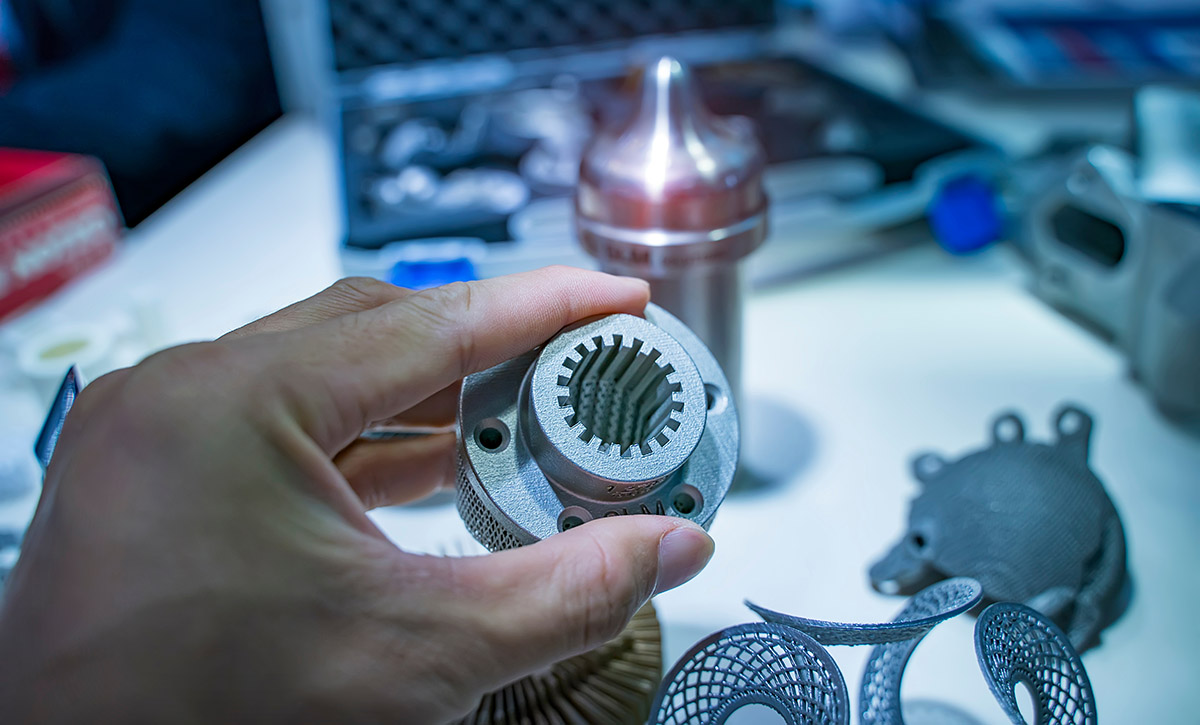

Metal 3D printing is transforming the plastics industry by enabling the production of complex mold inserts, reducing lead times, and enhancing design flexibility.

It offers significant benefits such as improved cooling channels, reduced weight, and increased tool life. However, choosing the right metal 3D printing technology requires a thorough understanding of available methodologies. This article delves into the methodologies of metal 3D printing, comparing them and evaluates their qualitative costs and performance.

You can also read: 3D Printing Waste: Printerior Designs’ Recycling Program

Key Metal 3D Printing Technologies

There are several methods to 3D print in metal, but here are the main methods used by the industry:

- Selective Laser Melting (SLM)/Direct Metal Laser Sintering (DMLS): SLM and DMLS use a laser to selectively melt or sinter powdered metal layer by layer. These methods are widely used for producing high-density, high-precision components from various metals, including titanium, aluminum, and stainless steel.

- Electron Beam Melting (EBM): EBM employs an electron beam to melt metal powder in a vacuum. This technology is well-suited for aerospace and medical applications, particularly for titanium alloys, due to its ability to produce strong, dense parts.

- Binder Jetting: Binder jetting involves selectively depositing a binding agent onto a bed of metal powder. The green part is subsequently sintered in a furnace to fuse the powder. This method is efficient for larger parts but typically results in lower densities compared to laser-based processes.

- Directed Energy Deposition (DED): DED uses a focused energy source (laser or electron beam) to melt metal feedstock (powder or wire) as it is deposited. This process is ideal for repairing existing components or building large structures.

SWOT, Costs and Performance Comparison

| Technology | Advantages | Disadvantages | Cost Considerations | Minimum Layer Height (µm) | Max Speed (mm/s) |

| SLM/DMLS | High precision and density- Supports complex geometries | High energy consumption- Expensive machines and powders | High initial investment- Medium-to-high operational costs | 20-50 | 10-50 |

| EBM | Excellent for titanium- Dense, strong parts- High build rate for large parts | Surface finish less smooth- Limited material choices | Expensive equipment- Medium-to-high operational costs | 50-100 | 50-100 |

| Binder Jetting | Cost-effective for large parts- High throughput | Lower density parts- Requires post-processing | Lower equipment cost- Lower operational costs | 200-300 | 100-400 |

| DED | Suitable for large parts and repairs- High material efficiency | Limited detail and precision- Requires skilled operators | Medium equipment cost- Low operational costs | 250-500 | 10-100 |

Costs Analysis

- Material Costs: High-quality metal powders can be expensive, especially for technologies like SLM or EBM.

- Machine Costs: Laser and electron beam systems are high-capital investments, often ranging from $300,000 to over $1 million.

- Operational Costs: Energy consumption and maintenance add to ongoing expenses. For example, SLM systems require inert gas environments, increasing operational costs.

- Post-Processing: Many processes require additional steps like heat treatment or surface finishing, which add to the time and expense.

Performance Factors

Factors affecting the performance of metal 3D printing include

Factor | Description |

| Quality of Raw Material | Impacts part strength, density, and overall performance. |

| Environmental Control | Ensures stable conditions to avoid defects due to temperature or humidity variations. |

| Power Supply | Sufficient power is required to maintain consistent processing during production. |

| Surface Finish | Poor surface quality affects fatigue strength and requires costly post-processing. |

| Porosity | Microscopic cavities reduce density and strength, leading to cracks or failures. |

| Density | Higher density (above 99%) is essential for critical applications. |

| Residual Stress | Stress buildup can cause warping or cracking of parts. |

| Cracking | May occur due to solidification defects or insufficient melting during the process. |

Even when we are talking about more precision and higher density, the bottleneck is still to reach in 3D Metal Printing the strength as conventional machining, something that should be addressed for a new product design custom made for Additive Manufacturing.

The Future of Metal 3D Printing…

Selecting the right metal 3D printing technology hinges on balancing the specific needs of your application considering the design complexity, material properties, required precision, and cost constraints when making a choice. By understanding these technologies, you can align your manufacturing process with your product’s goals and ensure an optimal balance of performance and cost-efficiency. Even when we are talking about more precision and higher density, the bottleneck is still to reach the strength as conventional machining, something that should be addressed for a new product design custom made for Additive Manufacturing.

To read more: A review on advances in 3D metal printing