Inside Materials – PEEK

When extreme conditions demand superior performance, PEEK is the material of choice. It offers resistance, durability, and versatility across diverse industries.

High-performance polymers offer an attractive alternative to replace metal or ceramic components in various industries. However, many of these materials fail to meet the technical demands of extreme conditions. In such cases, PEEK (polyether ether ketone) emerges as an exceptional solution.

You can also read: Inside Materials – PVC

Initially developed for defense and military applications, PEEK has proven highly resistant to harsh environments. Its mechanical, thermal, chemical, and electrical properties make PEEK an ideal choice. These qualities enable it to perform well in the extreme conditions found in aerospace, medical, and oil and gas industries.

Although its cost is higher than other polymers, PEEK provides a unique combination of functionality and durability. Additionally, its recyclability enhances its long-term sustainability.

Exploring The Properties

This semicrystalline thermoplastic demonstrates excellent dimensional stability and outstanding resistance to sterilization at high temperatures. It also exhibits impressive creep resistance, ensuring reliable performance under prolonged loads. Furthermore, its dielectric properties and high melting (343 °C) and glass transition (143 °C) temperatures enhance its usability in demanding environments.

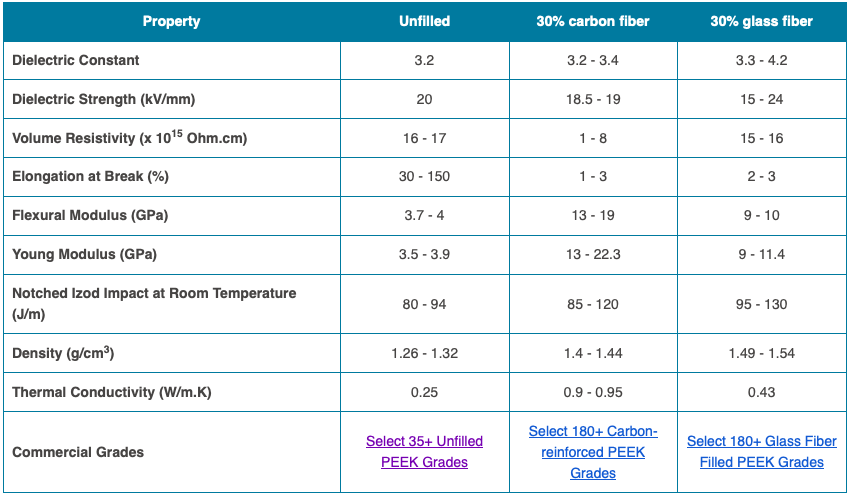

Table of properties for unfilled PEEK and PEEK reinforced with 30% carbon fiber or glass fiber. Courtesy of Omnexus.

The Versatility of PEEK

Manufacturers produce PEEK in various grades that should be carefully evaluated based on specific needs and manufacturing processes. It includes injection molding, compression molding, rotomolding, 3D printing, and CNC machining. This versatility enables the creation of both medical devices and complex industrial components.

PEEK applications include medical devices such as cranial implants and suture anchors. It is also used in internal gears, and tubing for coffee machines, as well as oil chambers in high-end e-cigarettes. It is even used in innovative products like chopsticks and fuel nozzle switches.

Common PEEK’ products. Courtesy of PEEK ARK INTERNATIONAL.

Case Study: Pre-Colored PEEK

One of the most notable recent innovations is Avient’s Colorant Chromatics™ Transcend™ line. It offers pre-colored, biocompatible PEEK compounds and colorants. This solution combines exceptional technical performance with advanced aesthetic options, meeting both functional and visual demands in the medical sector.

Key Industry Leaders and Market Overview

Imperial Chemical Industries (ICI) developed PEEK in the 1970s. In the 1990s, British Victrex acquired the PEEK business and became a leader in the field. Today, other key players, including Evonik, Solvay, SABIC, and Caledonian Industries, continue to shape the market. Valued at $799 million in 2023, the PEEK market is projected to grow at a CAGR of 8% from 2024 to 2030. This highlights the increasing demand for high-performance and sustainable materials across various industries.