Lignocellulosic Fibers for Sustainable Composites

In an era of the need for sustainable development and reduced environmental impact, lignocellulosic fibers (LCFs) have emerged as promising alternatives for creating eco-friendly engineering composites.

These natural fibers are attracting significant interest because they have the potential to replace synthetic fibers in various applications. Understanding LCFs and how they contribute to sustainable material development is essential for advancing green engineering solutions.

You can also read: Pros and Cons of Natural Fiber-Reinforced Plastics in Automotive

The Building Blocks of Nature: Understanding Lignocellulosic Fibers

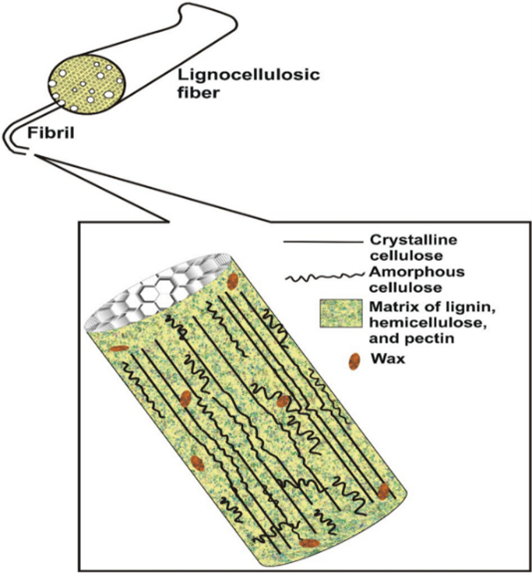

Lignocellulosic fibers (LCFs) are natural materials found in plant cell walls, composed primarily of cellulose, hemicellulose, and lignin. Cellulose, a crystalline and linear polymer, provides structural strength and rigidity while offering tensile strength due to its resistance to moisture penetration. Hemicellulose, a more amorphous and hydrophilic group of polysaccharides, binds cellulose microfibrils together but is less thermally stable.

Lignin, an amorphous polymer, adds stiffness and is a bonding agent with hydrophobic properties, although it can pose compatibility challenges with specific polymers.

Structural representation of a lignocellulosic fiber. Courtesy of Springer Nature Link.

Advantages of Lignocellulosic Fibers

Lignocellulosic fibers (LCFs) offer numerous advantages and play a crucial role in creating sustainable composites, supported by their natural renewability.

Moreover, LCFs derive from widely available plant materials like jute, flax, bamboo, and hemp, ensuring resource efficiency and environmental compatibility.

Additionally, their inherent biodegradability allows them to decompose naturally, reducing pollution and offering an eco-friendly alternative to synthetic fibers.

Beyond sustainability, LCFs exhibit remarkable mechanical properties, including high tensile strength and flexibility, enhancing the performance of composite materials effectively.

Their low density further supports lightweight designs, which are essential for improving efficiency and reducing emissions in various high-performance industries.

For example, the automotive industry uses LCF-based composites for interior panels, door trims, and components to reduce weight and boost energy efficiency.

Similarly, construction industries employ LCFs in insulation boards, lightweight panels, and sustainable building materials, offering thermal efficiency and durability.

Likewise, aerospace sectors benefit from LCFs’ superior strength-to-weight ratio, enabling the production of lighter yet robust components for aircraft structures.

Addressing Challenges and Enhancing Performance

LCFs face challenges such as moisture absorption, dimensional instability, and poor bonding with hydrophobic polymers, which reduce composite strength and durability, limiting their broader application. Experts need to develop innovative solutions to address these issues and enhance performance.

Researchers have addressed LCF challenges through chemical modifications like mercerization, which removes non-cellulosic components and enhances fiber-matrix bonding; acetylation, which reduces water absorption and improves stability; and silane treatments, which enhance compatibility and strength.

These techniques expand LCFs’ potential for high-performance composites across various industries.