Advanced Sandwich-Structured Composites

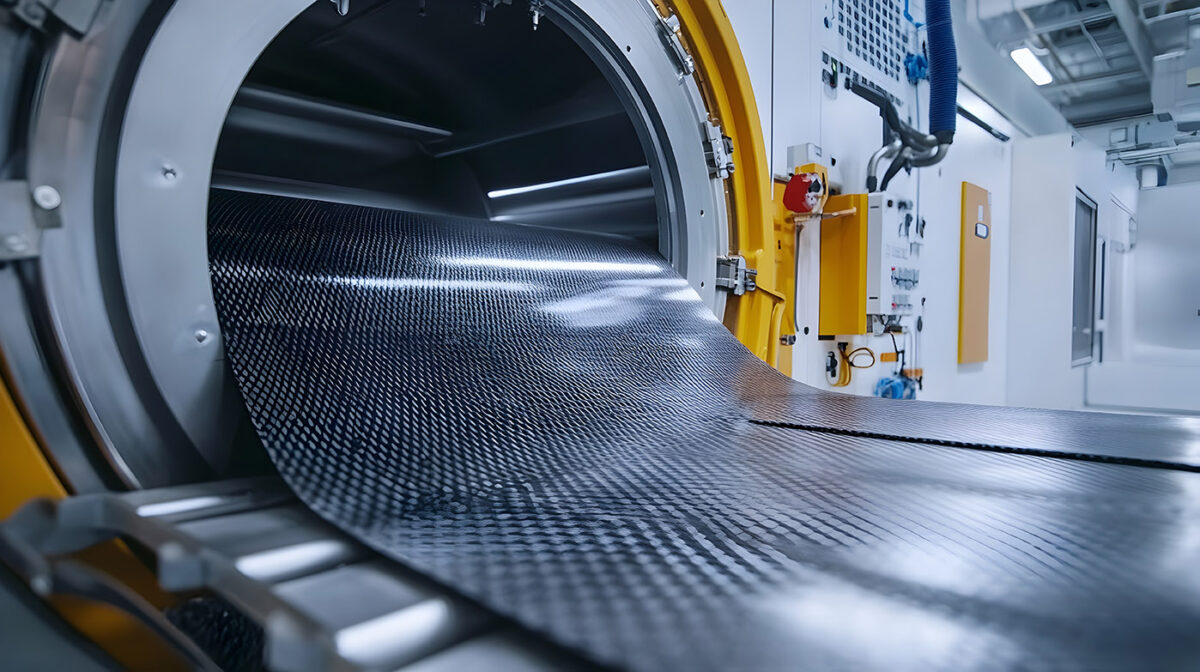

Researchers developed the Thermal Expansion Molding Process (TEMP), which aims to reduce high costs and improve inefficient large-scale production methods from traditional processes like autoclave molding and vacuum-bag-only (VBO).

Challenges in Traditional Manufacturing

Traditional processes like autoclave molding and vacuum-bag-only (VBO) technologies present significant challenges, including high costs and inefficient large-scale production methods. These methods frequently result in poor interfacial bonding and high energy consumption, which significantly restricts foam sandwich composites’ adoption. Consequently, aerospace, automotive, and sports industries encounter substantial limitations in utilizing these lightweight, high-strength materials for critical and advanced applications.

You can also read: Sandwich Injection Molding to Increase Post-Consumer Recycled Content.

Thermal Expansion Molding Process (TEMP)

To address these challenges, researchers developed the Thermal Expansion Molding Process (TEMP), which uses expandable epoxy foam as an internal pressure source. By heating the foam in a closed mold, TEMP generates controlled internal expansion pressure, creating intricate and reinforced sandwich composite structures.

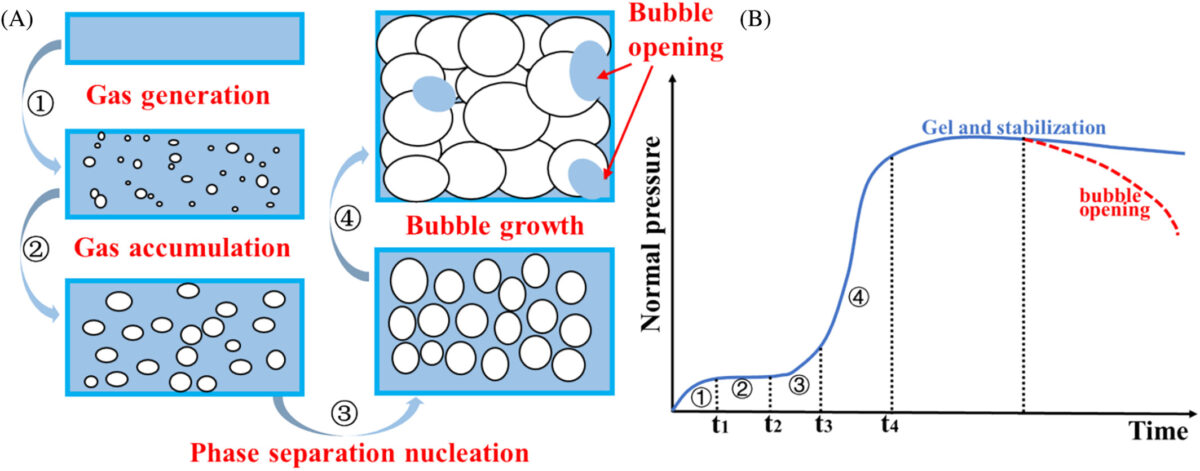

Schematic diagram of foam expansion: (A) foaming process of the polymer melt, (B) nominal normal pressure during restricted foaming. Courtesy of A new strategy for preparing web-reinforced foam sandwich composites with excellent mechanical properties.

Additionally, this innovative process simplifies manufacturing steps while reducing costs, offering superior interfacial bonding compared to traditional methods. Furthermore, TEMP allows precise control over directional expansion, making it ideal for producing complex and hybrid composite structures.

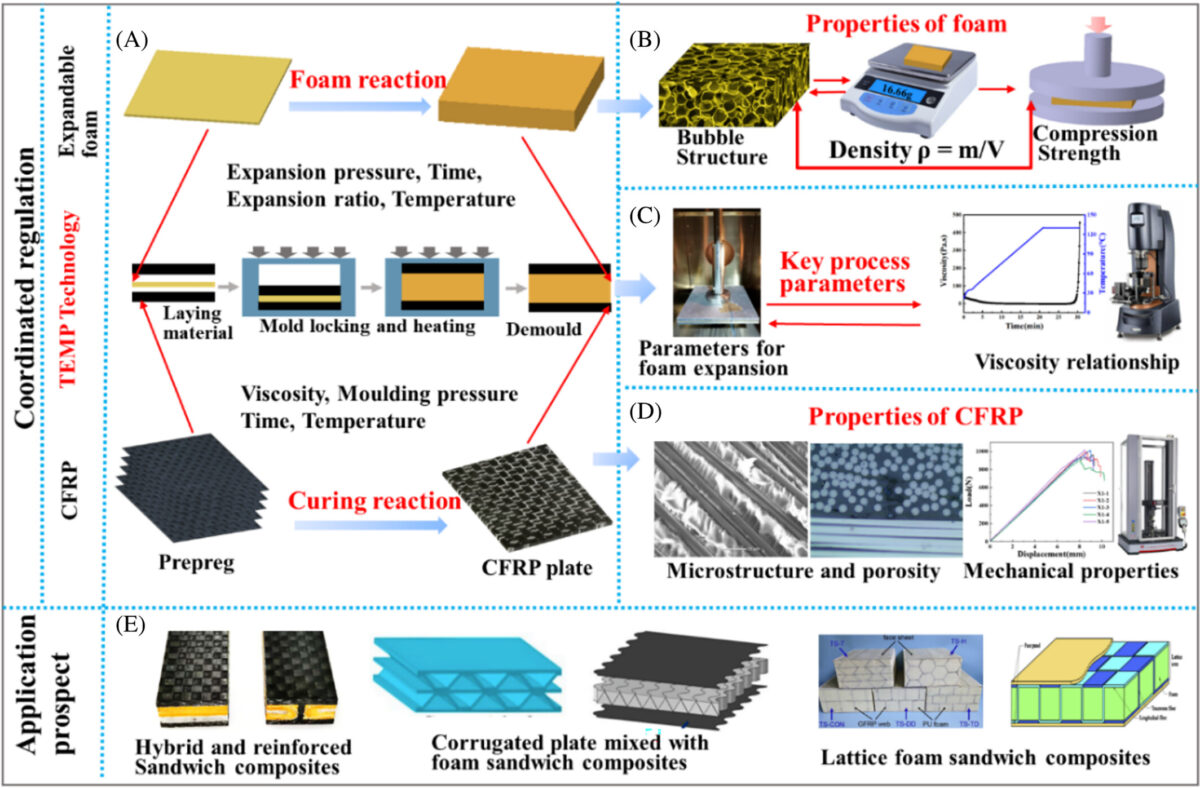

(A) The main technical route of TEMP technology to prepare sandwich composites, (B) the main experiments of foam properties, (C) the main experiments of coordinated regulation of key process parameters, (D) the main experiments of the properties of CFRP prepared by TEMP technology, (E) The main application prospect of TEMP stabilization control technology in sandwich composites. Courtesy of A new strategy for preparing web-reinforced foam sandwich composites with excellent mechanical properties.

Key Experimental Findings

Researchers conducted experiments to optimize TEMP by analyzing critical parameters like temperature, resin viscosity, expansion ratios, and curing times. They found that temperatures between 130°C and 140°C, combined with foam expansion ratios of 2 to 6 times, yielded the best results. Additionally, the study revealed that foams generating expansion pressures above 100 kPa were highly effective for composite molding, ensuring stability and reliability during production. This coordinated control of temperature, pressure, and resin viscosity enhanced the overall performance and consistency of the manufacturing process.

Enhanced Mechanical Properties

The TEMP method significantly improves the mechanical properties of foam sandwich composites, making them stronger and more durable than traditional counterparts. For instance, corrugated plate-reinforced composites achieved compression strength improvements from 4.81 MPa to 10.59 MPa, a notable performance leap. Moreover, the specific energy absorption of these materials increased from 2285.63 J/kg to 3864.63 J/kg. This Demonstraits their suitability for high-performance engineering applications. Consequently, TEMP-produced composites exhibit superior mechanical performance, setting a new benchmark for lightweight materials.

Broader Applications and Advantages

Foam sandwich composites produced using TEMP are highly suitable for industries demanding lightweight, strong, and durable materials for advanced applications. For example, the aerospace and automotive sectors benefit from TEMP’s ability to produce reinforced structures with better interfacial bonding and design flexibility. Moreover, TEMP offers significant cost advantages over traditional methods, making it an attractive choice for large-scale production. These features make TEMP a transformative solution for industries aiming to enhance efficiency and reduce production costs.

Future Outlook for TEMP

The Thermal Expansion Molding Process (TEMP) tackles inefficiencies in traditional methods by offering a reliable and cost-effective manufacturing solution. By carefully optimizing parameters like temperature, pressure, and expansion ratios, researchers demonstrated TEMP’s capacity to create lighter, stronger materials effectively. Furthermore, as industries place greater emphasis on sustainability and innovation, TEMP establishes itself as a groundbreaking method for advancing composite manufacturing technologies.

To read the study click here.