Advancing PVC Processing with Tung Oil-Based Heat Stabilizers

Researchers have developed two innovative tung oil-based liquid auxiliary heat stabilizers, Ph-T and Ph-TO, to address critical challenges in polyvinyl chloride (PVC) processing.

These stabilizers improve the thermal stability of PVC and enhance its plasticity, offering a sustainable and cost-effective alternative to traditional methods.

You can also read: Improved PVC Durability for Microplastic Prevention.

Overcoming Zinc Burning and Enhancing Stability

In PVC processing, zinc and calcium stearate heat stabilizers prevent degradation caused by hydrogen chloride (HCl) release during manufacturing. However, zinc-based stabilizers cause “zinc burning,” where ZnCl2 formation accelerates degradation, leading to discoloration and reducing the PVC processing window.

Tung oil-based stabilizers, Ph-T and Ph-TO, synergize with traditional stabilizers to address this issue and delay zinc burning effectively. By doing so, they extend the processing window, allowing the addition of essential materials like lubricants, pigments, or other processing aids. This extended time also enhances PVC fault tolerance, enabling its application in complex and structurally precise manufacturing processes.

Dual Benefits: Stabilization and Plasticity

Ph-T and Ph-TO offer dual advantages by improving PVC’s thermal stability while enhancing its plasticity. These stabilizers contain ester groups that interact with the PVC matrix to increase free volume, resulting in improved flexibility and lower glass transition temperatures (Tg). This property is particularly valuable for applications requiring flexible materials, such as medical-grade blood bags and cable sheathing.

Sustainable and Cost-Effective Innovation

The preparation process for Ph-T and Ph-TO is straightforward, requiring no heating, which reduces production costs and energy consumption. Derived from tung oil, a renewable resource, these stabilizers provide an eco-friendly alternative to traditional metal-based additives, aligning with growing demands for sustainable solutions in plastics manufacturing.

Mechanism of Action

Ph-T and Ph-TO stabilize PVC by substituting unstable chlorine atoms with secondary amines, preventing the accelerated release of HCl. Additionally, their decomposition products react with PVC’s conjugated double bonds, reducing discoloration and improving thermal durability. This mechanism ensures higher-quality PVC products with enhanced lifespan and aesthetic properties.

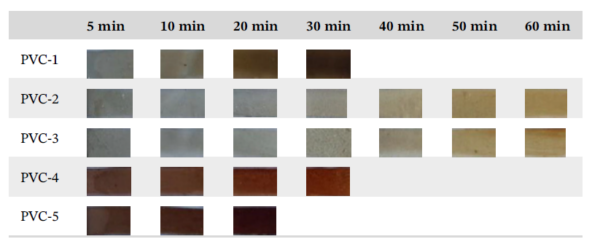

PVC aging. Courtesy of Preparation and properties of two types of tung oil-based

liquid auxiliary heat stabilizer for polyvinyl chloride processing.

Transforming PVC Manufacturing

Tung oil-based stabilizers enhance PVC processing by addressing thermal degradation and improving plasticity, thus marking a significant breakthrough. Furthermore, these bio-based additives ensure safer manufacturing practices and support advanced applications in medical, industrial, and consumer products. As a result, the plastics industry can adopt greener solutions while innovations like Ph-T and Ph-TO redefine efficiency and environmental responsibility.

To read the complete study click here.