Optimizing Fiber Diameter in Spunbond Nonwoven Fabrics

Researchers recently optimized fiber diameter for nonwoven fabrics using advanced statistical tools, enhancing production efficiency and fabric performance for diverse applications.

Optimize Production Using Statistical Designs

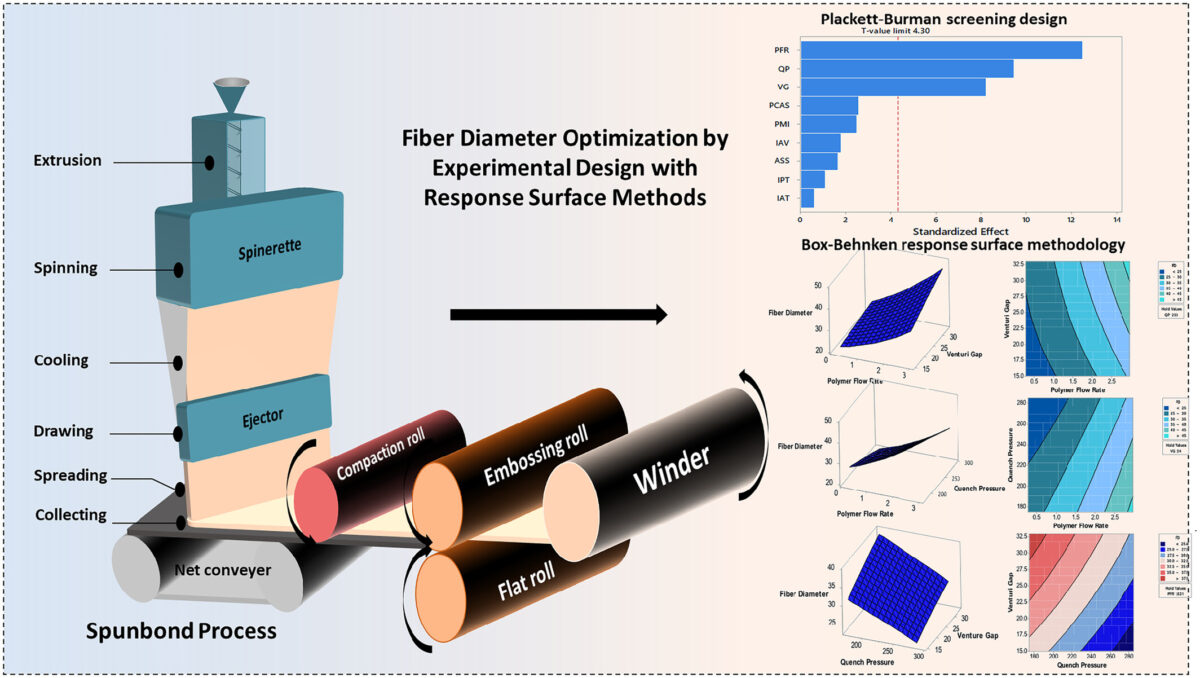

Fiber diameter (FD) plays a crucial role in defining the mechanical properties of spunbond nonwoven fabrics, researchers used Plackett–Burman Design (PBD) to analyze nine factors influencing FD, including polymer flow rate (PFR), quench pressure (QP), and venturi gap (VG). They identified these three factors as the most significant contributors.

You can also read: Revolutionizing Textiles: Innovative Coatings for a Cool-Touch Effect.

Using Box–Behnken Design (BBD), they refined the analysis and developed a regression model to quantify the relationships. Their results showed that increasing PFR and VG led to larger FDs, while raising QP reduced FD. These findings enabled researchers to propose clear optimization strategies for improving the spunbond process.

Fabrication process of spunbond nonwoven fabrics and fiber diameter optimization through experimental design and response surface methodology. Courtesy of Experimental analysis on fiber diameter of spunbond nonwoven fabrics through Plackett–Burman and Box–Behnken designs and its impact on mechanical properties.

Achieving Consistent Fiber Diameter

Researchers identified optimal conditions for achieving an FD of 31.0 µm. They adjusted PFR to 1.0752 g/min, QP to 175 Pa, and VG to 20.82 mm. These settings allowed consistent and high-quality fabrics to be produced while minimizing waste and energy consumption. The adjustments provided a reliable framework for scaling the process to industrial applications.

Researchers Link Fiber Diameter to Fabric Strength

The study highlighted the direct impact of FD on fabric properties. Researchers found that thicker fibers with larger FDs provided higher tensile strength and stiffness, making them suitable for demanding applications like geotextiles and automotive substrates.

In contrast, thinner fibers offered greater flexibility, which made them ideal for filtration, medical uses, and thermal insulation. By tailoring FD, manufacturers can customize nonwoven fabrics to meet specific performance requirements for various industries.

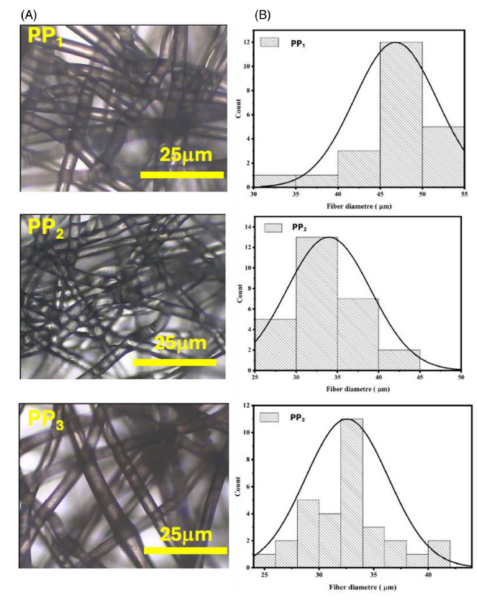

(A) Microscopic views of the nonwoven fiber diameters. (B) Distribution of

fiber diameters for the three samples. Courtesy of Experimental analysis on fiber diameter of spunbond nonwoven fabrics through Plackett–Burman and

Box–Behnken designs and its impact on mechanical properties.

Advancing the Future of Nonwoven Fabrics

The research emphasizes the importance of systematically optimizing parameters in the spunbond process. By focusing on PFR, QP, and VG, manufacturers can improve fabric quality and reduce costs. Moreover, to build on these findings, researchers plan to validate their results at industrial scales and incorporate machine learning models like neural networks to refine process control. These efforts promise to revolutionize nonwoven fabric production, ensuring both exceptional performance and sustainability.

Conclusion

Through active process optimization, this study provides actionable strategies to enhance the performance of spunbond nonwoven fabrics. By controlling fiber diameter, manufacturers can achieve a balance between strength, flexibility, and efficiency, driving innovation across industries while ensuring sustainability in production.