Inside Materials – PEF

PEF represents the next generation of sustainable PET by combining high-performance quality with sustainability—two essential requirements for today’s consumers.

As sustainability reshapes the plastic packaging industry, companies actively pursue alternatives to PET. One of the most promising options is PEF (polyethylene furanoate). This biopolymer is derived from renewable resources, specifically plant-based sugars such as fructose and glucose.

You can also read: Inside Materials – Polycarbonate

What is PEF?

Manufacturers produce PEF by polymerizing ethylene glycol and 2,5-furan dicarboxylic acid (FDCA), a compound that replaces terephthalic acid in PET’s structure. This substitution allows PEF to retain many of PET’s key properties while adding benefits in terms of sustainability and performance.

PEF vs. PET: Key Advantages

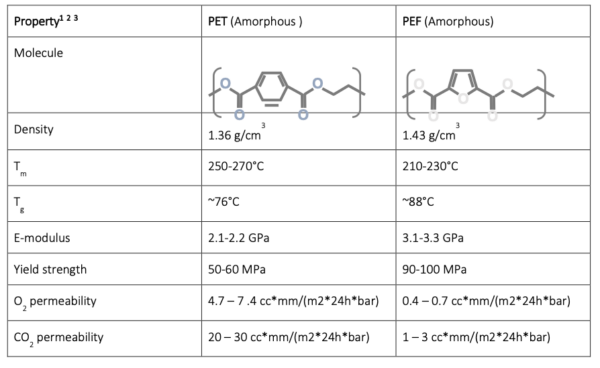

PEF provides several advantages over PET, including a lower carbon footprint and enhanced thermal, mechanical, and barrier properties. For example, PEF offers up to six times greater resistance to CO₂, making it ideal for applications needing high impermeability and durability. The table below illustrates specific performance comparisons.

Comparison Chart of PEF and PET Properties. Courtesy of Avantium.

Applications of PEF

PEF’s outstanding properties are driving its demand across various industries. Experts project that the global market for this biopolymer will reach USD 28 million by 2028. The highest adoption of Polyethylene Furanoate is seen in packaging, followed by the fiber and textile industries. Additionally, its versatility enables its use in sectors like automotive, pharmaceuticals, electronics, and electrical applications.

Challenges and Avantium’s New FDCA Plant

Despite its exceptional qualities, manufacturers have faced significant challenges in scaling up PEF production to an industrial level. This is due to high production costs and technical complexities associated with processing FDCA. However, after years of development, Avantium recently celebrated the opening of the world’s first commercial FDCA production plant on October 22. This milestone represents a significant advancement toward making Polyethylene Furanoate more widely available.

Opening of Avantium’s FDCA Flagship Plant. Courtesy of Avantium.

You can also read: Origin, Husky Claim ‘Commercialization Milestone’ for Advanced Packaging

Additional Leading Players

In addition to Avantium, other leading players in the Polyethylene Furanoate market include Sulzer, ALPLA Group, Origin Materials, Toyobo, and Danone. Each company is committed to advancing PEF as a potential sustainable bioplastic to replace several fossil-based polymers.