Rotational Molding: Balancing Sustainability and Performance

In response to the shifting demands of the rotational molding industry, companies are developing pioneering technologies to reduce cycle times and integrate recycled content into advanced materials.

In a recent interview, Jake Kelly-Walley, R&D Engineer at Matrix Polymers, discussed the challenges and advancements within the rotational molding industry. This sector focuses on creating hollow plastic products and balances performance, sustainability, and innovation. As a specialist in material development, Jake shared valuable insights into the intricacies of rotational molding, the role of sustainable materials, and the future of the industry, particularly in the context of the growing hydrogen sector.

You can also read: Robotic Rotational Molding: Precision, Sustainability, and Efficiency

The Dynamics of Rotational Molding

Rotational molding stands out due to its ability to create uniform, stress-free products with minimal material waste.

According to Jake, a vital advantage of this process is its high material efficiency: “Everything you put into the mold is what you consume, resulting in very low waste.”

Rotational molding process, courtesy of Matrix Polymers.

However, a significant drawback tempers this efficiency—long cycle times. While industries like injection molding have developed ways to produce parts rapidly, rotational molding remains a time-intensive process.

To solve this, companies like Matrix Polymers invest in R&D to speed up the process. “Designing materials with faster cycle times without compromising on performance is a major area of focus,” Jake explains. Innovations like tailored polyethylene blends and specialized barrier resins aim to reduce cycle times, making the process more cost-effective and energy-efficient.

Sustainability and Performance: Finding the Balance

With growing pressure to adopt more sustainable practices, the use of recycled and biopolymer materials is becoming a pivotal trend in the industry. Jake points out that incorporating recycled content in rotomolded products is a considerable challenge. Recycled materials often have high viscosity, making processing difficult. This affects consistency and strength compared to virgin materials. To overcome this, Matrix Polymers has been experimenting with advanced stabilization methods that improve the performance of recycled feedstocks, making them more suitable for demanding applications.

You can also read: Sustainability in Plastic Part Design: The Indispensable Fifth Dimension

Biopolymers derived from renewable resources are another area of exploration. These materials, while promising, must meet stringent performance criteria to be viable alternatives. As such, the R&D team is working to synthesize biopolymer blends that can withstand the rotational molding process while also contributing to reduced carbon footprints.

Pioneering Technical Solutions for Type IV Hydrogen Vessels

A significant highlight of the discussion was Matrix Polymers’ innovative efforts in developing materials for hydrogen vessels. These vessels, crucial for the hydrogen economy, are essential for storing compressed hydrogen gas used in energy storage and transportation.

You can also read: Rotomolding: A Key Process in Hydrogen Tank Production

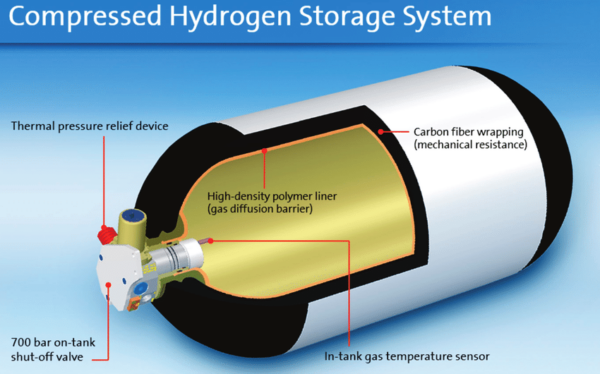

Type IV vessels feature a composite structure with a polymer liner overwrapped with carbon fiber, ensuring durability and functionality. The polymer liner serves as a barrier against hydrogen permeation, while carbon fiber reinforcement maintains structural integrity under high pressure.

Type IV 70 MPa compressed gaseous hydrogen vessel. Taken from Adam Opel AG, GM Alternative Propulsion Center.

However, preventing hydrogen permeation in polymer liners remains challenging, given hydrogen’s small molecular size that easily permeates conventional materials. To address this, Matrix Polymers engineered specialized solutions like Revolve® EVOH and Revolve® PA RDN, offering superior performance.

Revolve® EVOH, a dual-layer structure based on PE-modified technology, forms a chemical bond between EVOH and PE during roto molding. This innovation provides exceptional barrier properties against hydrogen, ensuring secure storage even under high-pressure conditions.

Meanwhile, Revolve® PA RDN, a modified Polyamide 6, offers enhanced thermal resistance and superior mechanical properties like increased flexural modulus and tensile strength. These characteristics are vital for hydrogen applications, where durability and resistance to permeation are critical for success.

Focusing on sustainability and performance, Jake and the Matrix Polymers team are transforming rotational molding for future applications in hydrogen. Their dedication to innovation ensures that rotational molding remains a pivotal manufacturing process in the plastics and hydrogen industries.