Essential Tips for Designing Injection Molded Parts

Understanding how the process’s nature may induce deviations from the part design is crucial to meeting quality requirements in any molding project.

Understanding the Process

One of the most common mistakes is designing plastic parts without understanding the manufacturing process used to produce them and how it will affect the result. Over my career working in injection molding, I have often seen designers confronted with deception when the plastic parts they conceived look flawed after molding.

You may also read: Design-Related Surface Defects in Injection Molding

However, this has to do with the lack of understanding of how a part will fill and cool during injection molding. The inherent nature of the injection molding process includes high shearing and high orientation. Therefore, it is expected to have marks that show these flow paths, which are usually unwanted from the aesthetic and quality point of view.

Also, cooling and solidification involve part shrinkage and warpage. Any temperature gradient induced during molding will cause an individual cooling rate at each part region, thus affecting crystallization and contraction.

Therefore, it is crucial to understand how the injection molding process’s nature may affect the molded component’s appearance and which decisions may be induced.

You may also read: 3 Common Injection Molding Challenges and How to Solve Them

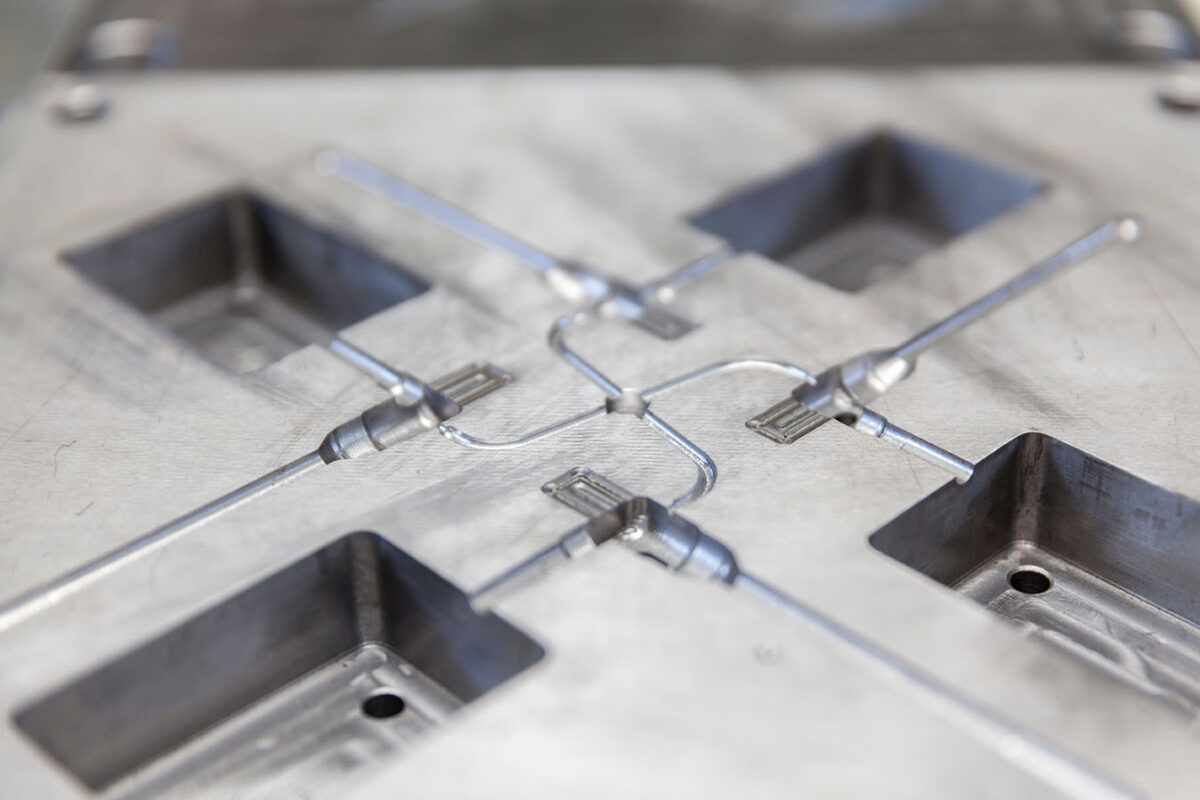

The Importance of Gating

Choosing the gate position is one of the most critical decisions in any injection molding project.

The position of gate is one of the most crucial decisions you will ever make in an injection molding project. It affects not only the part filling, but also the packing (compensation of the volume contraction), the aesthetics and the part mechanical performance.

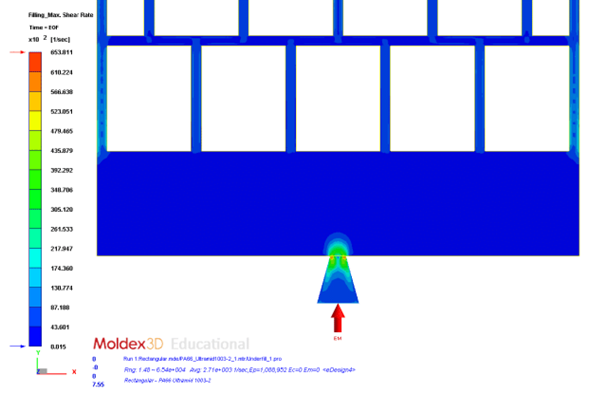

The start of the filling pattern is always a hot spot and high shear region. If it is too narrow, it may lead to material or masterbatch degradation, changing the part color or leaving unwanted marks. Shear stresses are normally two orders of magnitude higher at the gate than at any other location within the part. This high shear can degrade shear-sensitive polymers and additives.

Because it will also be the source of hot material incoming inside the mold, at the gate a hot spot appears, and therefore it will also induce high molecular movement. Sometimes it may even lead to cracking, due to concentration of residual stresses around it.

Also, the position of weld lines in the part depends on the gating position. Weld lines are weak spots inside the part and may affect the mechanical performance and the part appearance. Predicting the position of the weld lines and the air trapped at this point during filling is a task that needs to be accomplished early at the design stage. Here simulation tools can help, and a 15-minute simulation can save a lot of stress afterwards in the molding process.

Avoid Mass Concentrations

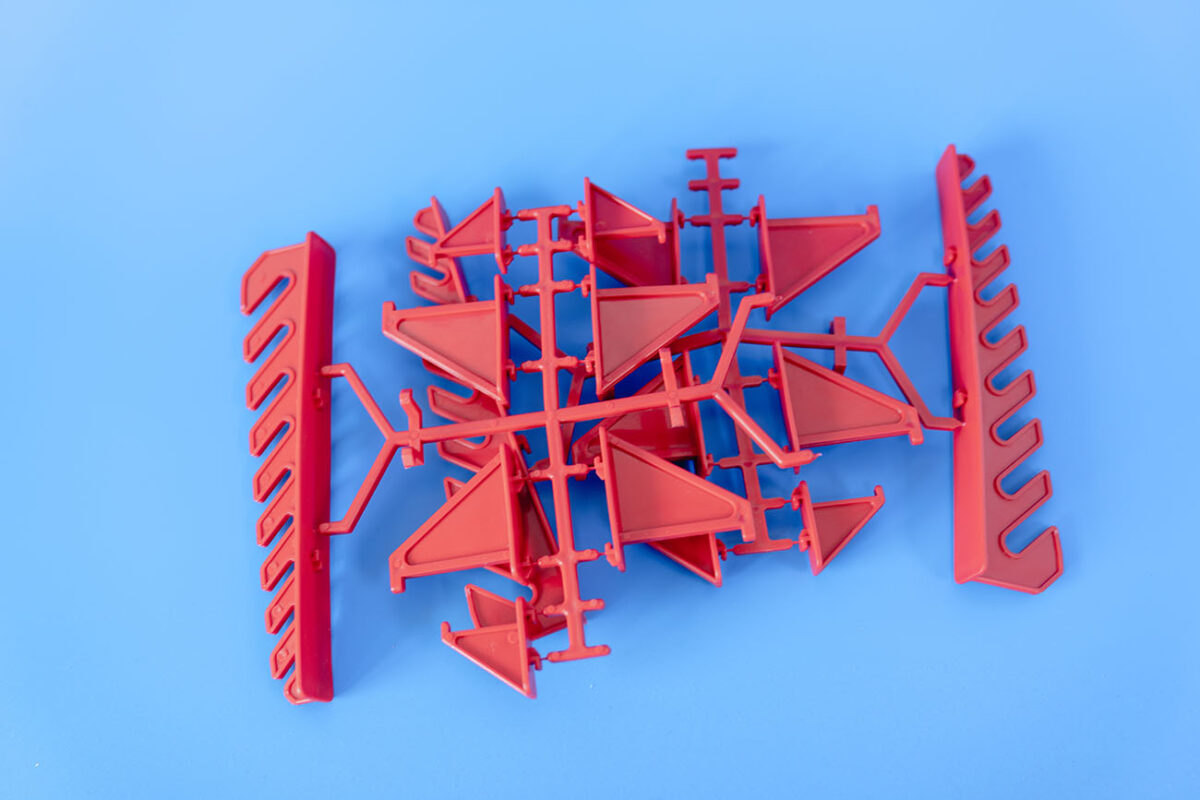

Gate is often the region of the part with the highest shear rate. Source: Impact of Viscosity on Filling the Injection Mould Cavity.

The number one rule in injection molding is designing parts as thin as possible. The second one is to design with constant part thickness. Both have to do with the need to reduce cycle time and, most importantly, temperature gradients within the part.

Always think that the thicker the part, the slower the cooling. At very slow cooling rates molecules have a lot of time to rearrange and shrink. In semi-crystalline polymers this rearrangement will always take the form of higher crystallization, and larger crystallization means also higher shrinkage.

It is unwise to have a region of the part with more shrinkage than others. The thicker region will always pull the parts around it, generating either residual stresses or warpage, sink marks and voids.

When designing always think also that any region where material is accumulated will leave a region with late solidification. If around it all the material solidifies, this island of materials remains isolated and will solidify without compensation of volume contraction through packing, as it will be disconnected from the gate.