What Makes Lignin Special?

There are many great qualities lignin possesses. This natural polymer is a potential alternative to fossil-fuel-derived plastic but comes with its fair share of challenges and hold-ups.

As government representatives formalize legislative changes, the movement towards renewable alternatives for plastic pushes forward. Academic researchers and beyond invest time, money, and energy into innovative bio-based solutions to petroleum-based plastic products and materials. One researcher at Clemson University is doing just this. Plastics Engineering spoke with Dr. James Sternberg in Clemson’s Department of Food, Nutrition, and Packaging Sciences (FNPS) about his ongoing research into this natural polymer.

You Can Also Read: Transforming Food Packaging: The Shift to Biopolymers?

Dr. Sternberg is a Principal Investigator (PI) at Clemson University. The philosophy behind his lab is to redesign plastics to address the major critical areas of the plastic problem today – problems such as degradability and toxicity. One of his ongoing projects focuses on lignin, a natural polymer counterpart to cellulose and hemicellulose in trees and plants. So, what makes this natural polymer special? What are the problems researchers face today and is there a bright side? Research advances in recent years highlight lignin in plastic applications like packaging, yet lignin may still be far from a plastic replacement option. Understanding the challenges and contributing research into viable solutions inches us closer to commercialization and consumer-driven products.

Renewable Alternatives

The special thing about lignin – it’s a unique aromatic compound formed with aromatic rings, which give it high-strength characteristics. Many people are looking into lignin for its potential in creating high-performance materials. – Dr. Sternberg, Clemson University

Refined lignin. Image courtesy of sappi.

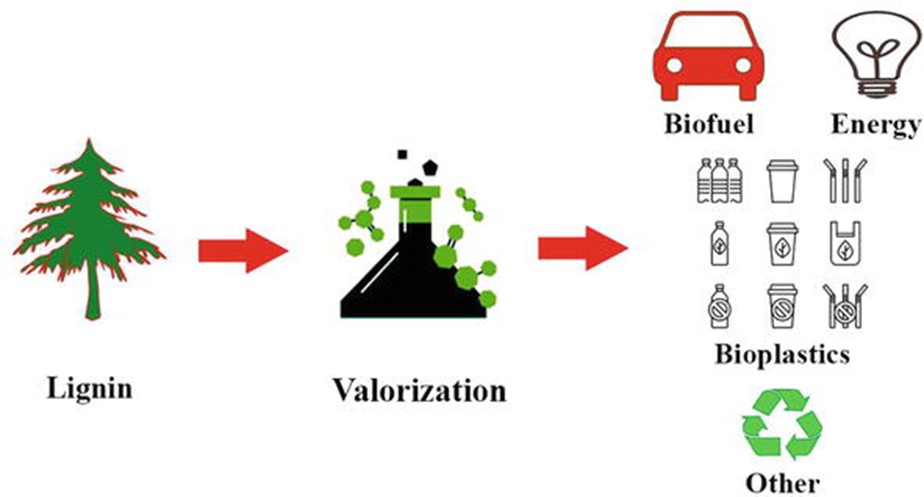

Lignin is the rigid component of trees and plants. It is a high-strength natural material composed of aromatic carbon compounds. These aromatic rings create a three-dimensional structure that gives its strength and stability, qualities cellulose lacks. Further, it is a readily abundant biopolymer. It is the second most abundant natural source of carbon, behind cellulose, and can provide a significant portion of renewable energy contingent upon new conversion processes. It has industrial value and can potentially be valorized into fuels, valuable chemicals, and other products. The use of renewable alternatives have the potential to impact health, energy security, and climate change. Extracting and converting lignin is complex and can require a significant amount of energy. Researchers like Dr. Sternberg are working to refine the conversion process, creating products such as foam that could potentially go to market.

Production Challenges for Lignin

Lignin valorization schematic. Image courtesy of IntechOpen.

The creation and production of efficient and industry-ready biopolymers is a pressing matter. Research studies focusing on converting lignin into valuable products are essential, though only some of these efforts have been commercially successful. Turning lignin extraction and conversion into an economically viable process that results in high-value products can be difficult. This is due to the complex and energy-intensive nature of the extraction and conversion processes, which can result in unwanted side reactions and byproducts. Additionally, lignin obtained from the pulping process typically comes as a heterogeneous mixture that is highly altered and degraded. Alternatively, lignin-first methods extract lignin in a way that preserves its functionality. However, many of the preservation techniques are still in the research stage. Further, lignin can become quite reactive when exposed to high heat. High temperatures will cleave lignin C-O bonds, resulting in recalcitrant compounds that lose their functionality and value. Thus, lignin isolation, purification, and characterization studies are needed steps to move forward and help bring lignin to center stage. Unleashing lignin’s potential is possible but will take additional research and refinement.

Chemicals like polyethylene and polypropylene didn’t get to where they are in a day. They were refined over decades. We must keep working on making these technologies ready. We must keep refining them. – Dr. Sternberg, Clemson University

The Bright Side

The good news? Lignin is still a hopeful biopolymer like its cellulose counterpart. Researchers across many scientific disciplines, like Dr. Sternberg and his colleagues, are working on said lignin-specific challenges. The scientific community is exploring novel extraction, conversion, and valorization methods to turn lignin into an industrial-scaled valuable product in applications like plastic packaging, apparel, automotive applications, and more. In addition, commercial attempts to replace fossil-fuel-derived plastics with lignin-based products are underway. For example, companies such as StoraEnso are developing, manufacturing, and selling products such as lignin-based adhesives. In time, the commercialization of this natural polymer will fall into the consumer’s lap. When consumers demand more sustainable alternatives, a sustainable future becomes our reality. In the interim, researchers will work tirelessly to refine processes and scale-up methods for commercialization.