Upcycling Microplastics into Graphene

Researchers at James Cook University have developed a groundbreaking method to convert microplastics into graphene.

Microplastic pollution is an escalating environmental threat, contaminating ecosystems and entering the food chain due to its non-biodegradable nature. Despite the growing need for plastic waste management, traditional recycling methods remain inefficient and costly. Researchers at James Cook University have developed a novel technique called Atmospheric Pressure Microwave Plasma (APMP) that offers a breakthrough solution by upcycling microplastics into graphene, turning environmental waste into valuable materials.

You can also read: Do Plastic Bottles Release Microplastics?

The APMP Process: A Game-Changer

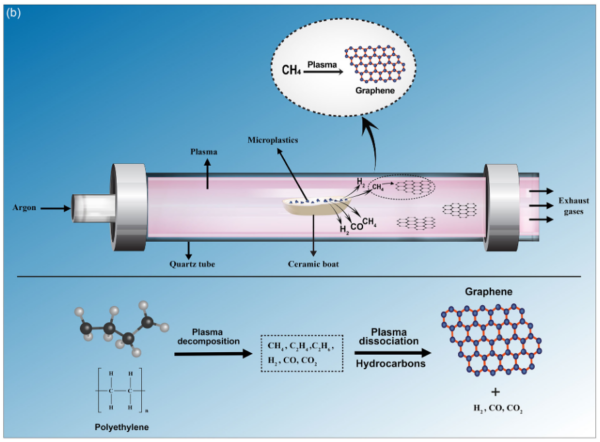

The APMP (Atmospheric Pressure Microwave Plasma) method significantly advances microplastic recycling. This process instantly transforms microplastics into graphene, bypassing the need for multiple steps typically required in traditional recycling techniques. Unlike other methods that rely on high-vacuum environments, catalysts, or substrates, APMP operates under atmospheric pressure, dramatically simplifying the process.

Schematic representation of APMP system for the synthesis of graphene from PE microplastics. Courtesy of Instant Upcycling of Microplastics into Graphene and Its Environmental Application.

This approach uses microwave plasma to vaporize polyethylene microplastics and restructure them into graphene sheets. Using atmospheric pressure, the APMP method saves energy and reduces costs, making it a much more practical option for large-scale applications. Moreover, this single-step process offers the added benefit of producing high-quality graphene with fewer structural defects than other recycling methods.

High-Quality Graphene Production

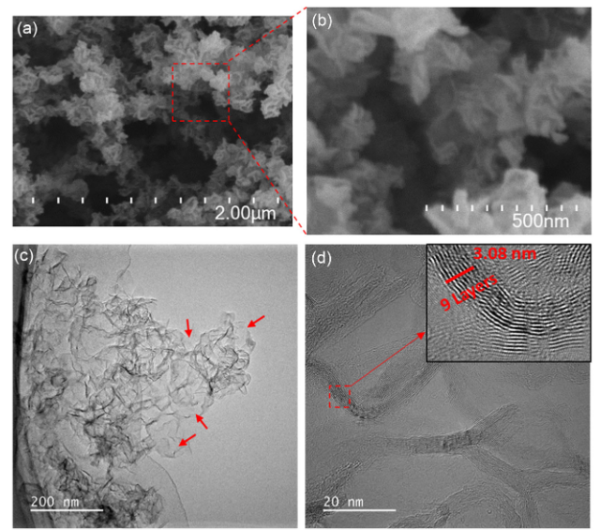

Graphene produced through APMP shows excellent structural integrity, with fewer defects than graphene made through other techniques like catalytic carbonization or flash Joule heating. This superior graphene quality opens up new possibilities for its use in advanced technological and environmental applications. For instance, APMP graphene has proven effective in adsorbing harmful chemicals like perfluorooctanoic acid (PFOA), showcasing its potential as a valuable tool in environmental cleanup efforts.

Low- and high-magnification SEM and TEM images of 500 W graphene sample. Courtesy of Instant Upcycling of Microplastics into Graphene and Its Environmental Application.

Environmental Impact and Sustainability

The ability to upcycle microplastics into graphene addresses the growing issue of plastic pollution and offers an innovative approach to sustainability. This method contributes to a circular economy by turning waste into valuable materials. It also represents a way to capture and upcycle microplastics from the environment.

The APMP method is a groundbreaking solution for tackling microplastic waste and the demand for advanced materials like graphene.Its energy-efficient, single-step process offers a scalable solution for converting plastic waste into high-quality graphene for industrial and environmental applications, combining innovation and sustainability for a cleaner future.