Styrene Foam: From Trash to Tech

Researchers have developed a method to recycle styrene foam into valuable electronic materials.

Styrene foam, commonly used in packaging, poses significant environmental challenges. Traditional recycling methods are often economically unviable. Consequently, finding ways to convert this low-value waste into high-value materials is crucial. The imidazolium-based sulfonation method proposes a solution that effectively addresses this issue.

You can also read: Rethinking the System: We Need Molecular Recycling

Introduction to Sulfonation

The sulfonation of aromatic polymers is a powerful approach to accessing high-value materials for various applications, such as ion-exchange resins and membranes, electronic materials, and pharmaceuticals. Researchers used an imidazolium-based sulfonating agent that allows for precise sulfonation of polystyrene, including expanded polystyrene (EPS) waste.

Transforming EPS Waste

The method transforms EPS waste into sulfonated polystyrene (PSS). This transformation upgrades the material, making it suitable for various high-value applications. For instance, one key application is creating conductive polyelectrolytes like PEDOT. These materials are essential for organic electrochemical transistors (OECTs) and hybrid solar cells.

Advantages of Imidazolium-Based Sulfonation

The imidazolium-based agent [Dsim]Cl offers several advantages over traditional sulfonating agents. It achieves high degrees of sulfonation with minimal side reactions. This precision ensures high yields and maintains polymer integrity, essential for producing high-quality materials. Additionally, this method is eco-friendly, reducing the need for harsh reagents and excessive waste.

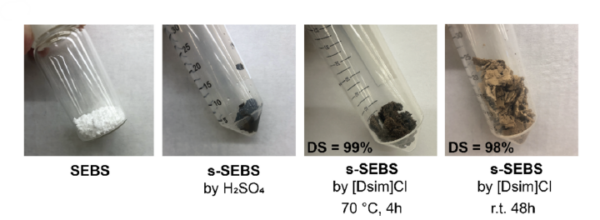

Photographs of styrene−ethylene−butylene−

styrene (SEBS) before and after Vink’s sulfonation, and imidazolium-mediated sulfonation at 70 °C for 4 h or room temperature for 48 h. Courtesy of Imidazolium-Based Sulfonating Agent to Control the Degree of Sulfonation of Aromatic Polymers and Enable Plastics-to-Electronics Upgrading.

Adding Value to Recycled Materials

By converting EPS into valuable electronic components, the method offers a sustainable solution to plastic pollution and opens up new avenues for research and development in polymer chemistry.

Researchers demonstrated that PEDOT derived from EPS waste performs comparably to commercial PEDOT. This finding highlights the potential for widespread industrial adoption of this method. Consequently, recycling styrene foam into high-value materials becomes a viable and attractive option.

The imidazolium-based sulfonation method provides a solution for recycling styrene foam. It converts low-value waste into valuable electronic materials, addressing environmental and economic challenges.