Pulp Injection Molding for Packaging Solutions

Injection molding has become more versatile, now accommodating various raw materials, including paper. This flexibility makes it suitable for packaging and pharmaceutical applications.

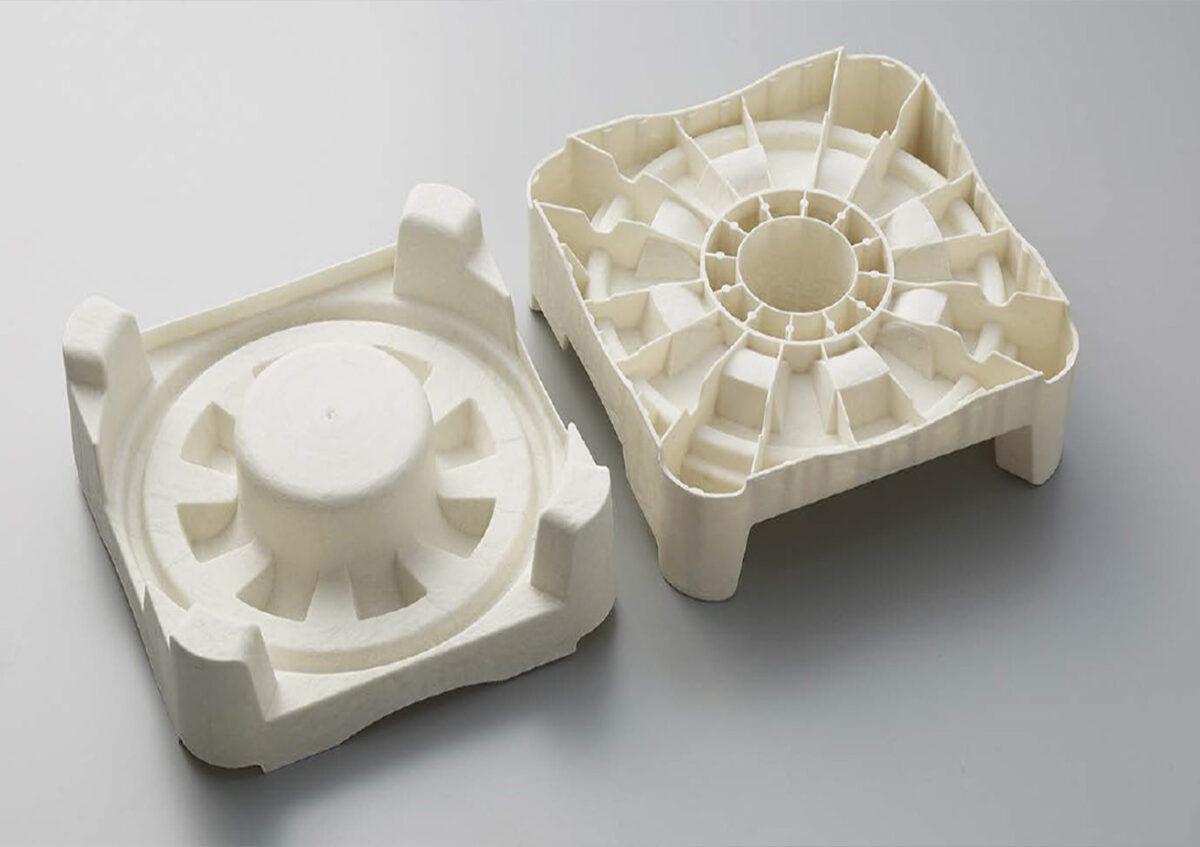

Pulp Injection Molding (PIM) enables manufacturers to produce unique and intricate geometries typically reserved for plastics but using paper. This innovation provides new options for brand owners, enhancing sustainability and design flexibility.

You can also read: Sandwich Injection Molding to Increase Recycled Plastic Content

How does it Work?

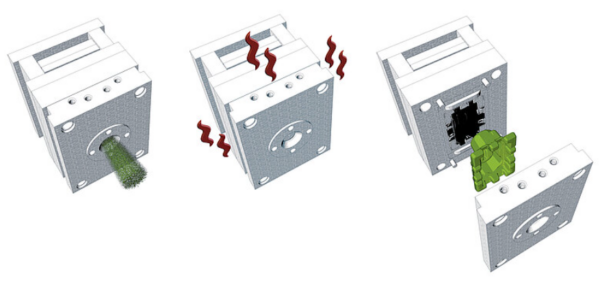

As a conventional injection molding process, pellets are heated and introduced into the mold cavity. In this case, the pellets are made from paper, starch, and water, so they have humidity. This is a major difference from plastic injection molding because the process needs to dry out the humidity from the material. Therefore, the cavity needs to open slightly several times during the injection.

Advantages from PIM

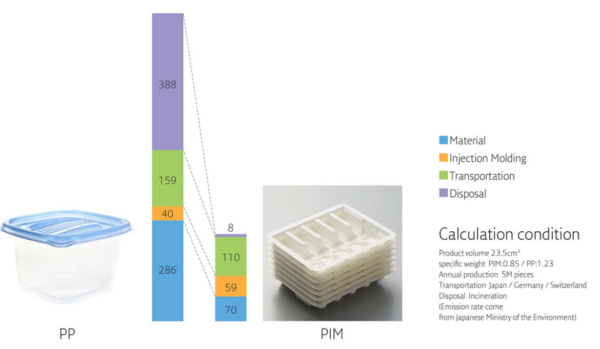

According to Nissha, a Chicago-based company, PIM has much more design freedom than other typical pulp-forming processes, such as pulp molds or box-folding processes. The benefits of PIM extend beyond aesthetics. According to Nissha USA, using paper pulp significantly reduces the production process’s environmental footprint as PIM utilizes renewable materials. Consequently, this aligns with the increasing consumer demand for products that are both high in quality and low in environmental impact.

Comparing with conventional plastic case made by PP(polypropylene) material, the life cycle CO2 emission of PIM technology is 72% lower. Courtesy of Nissha USA.

Is PIM the future of sustainable packaging design, or are there potential drawbacks that may hinder its widespread adoption in the industry?”,

“refusal