Nylon Replacing Metal Won an SPE Automotive Award

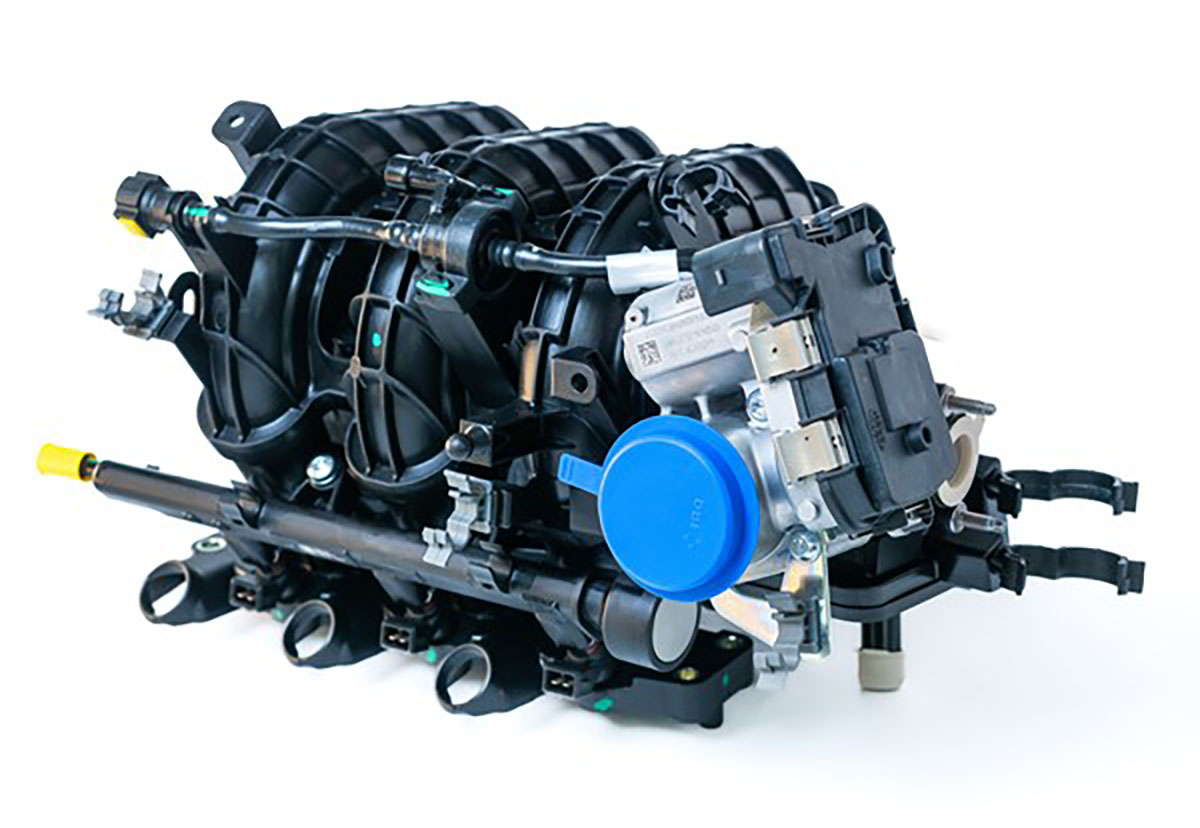

RadiciGroup recently won a SPE Automotive Award in Europe for helping develop an automotive air intake manifold for Marelli, which is made entirely of recycled nylon.

Marelli Group designed and manufactured the component, created by Calsonic Kansei Corp. in 2019 after acquiring Magneti Marelli SpA. This acquisition was from Fiat Chrysler Automobiles N.V., leading to the establishment of Marelli Group.

RadiciGroup officials accepted the honor in the powertrain category at the 22nd SPE Automotive Awards on June 28 in Bonn, Germany.

Nylon in Manifold Applications

Erico Spini, Cesare Clausi and Giacomo Viscardi of RadiciGroup High-Performance Polymers.

The Bergamo, Italy-based materials and chemicals supplier said the manifold is a high-technology automotive application. It noted that, over the years, glass fiber-reinforced nylon has almost completely replaced metal. The firm supplies nylon 6 and 6/6 materials for engines worldwide. Additionally, it describes Renycle as a family of low environmental impact and high-performance engineering polymers. The resins use selected and traceable raw materials based on post-industrial and post-consumer PA 6 and PA 6.6.

They said the challenge for this application was to use a 100 percent mechanically recycled polyamide material. This required careful selection, cleaning, and control of raw materials to ensure very high-quality consistency.

RadiciGroup officials said that in developing Renycle, the firm worked to optimize performance, considering the specific requirements of the air intake manifold application.

Marelli needed to meet stringent performance requirements. Specifically, these included high burst pressure, pressure pulsation, and prolonged vibration tests subjected to thermal cycles and thermal shocks. Furthermore, the firm said it paid particular attention to noise vibration harshness (NVH) analysis. They did so to ensure, among other things, acoustic performance in line with the other materials used today.

Using Recycled Nylon Slashed CO2 Emissions

RadiciGroup also sought to maximize the material’s environmental benefits. it said life cycle assessment methodology showed the resin reduced CO2 emissions by more than 70 percent compared to equivalent fossil source material.

SPE said the jury evaluated about 50 projects, many of which were aimed at making cars and motorbikes more sustainable.

“It is a great satisfaction for us to be recognized by the Society of Plastics Engineers,” said Erico Spini, global marketing director of RadiciGroup High-Performance Polymers. “This award valorizes the work and commitment we put in every day to give shape to truly innovative and valuable projects. Moreover, it recognizes our teamwork with Marelli, our long-standing customer ….

“These principles, or better yet our tangible results, are the basis of our global offering, which decisively raises the bar in the development of winning solutions from the viewpoint of sustainability. To sum up, we hope this application can give impetus to new initiatives fostering sustainable mobility.”