Advances in PTFE Recycling

Recycling fluoropolymers is complex but essential for environmental resource efficiency and several industries that depend upon their properties.

Fluoropolymers, particularly Polytetrafluoroethylene (PTFE), are indispensable in modern industries due to their unique properties, such as exceptional chemical resistance and thermal stability. These materials are widely used in various sectors, including electronics, automotive, and aerospace. However, the same durability that makes them valuable also creates significant challenges in recycling.

You can also read: Fluoropolymers: Waste Management and Sustainable Disposal?

Primary Recycling: Repurposing Sintered PTFE Waste

Primary recycling involves collecting, sorting, and grinding sintered PTFE waste into a free-flowing powder. This process allows the material to be reused, although it results in physical properties that differ from those of virgin PTFE. For example, reprocessed PTFE typically exhibits reduced tensile strength and elongation. However, it remains suitable for specific applications, such as ram extrusion processes where temperature and pressure are simultaneously applied. This method enables the repurposing of PTFE waste, reducing the need for new raw materials and minimizing environmental impact. Companies like Shamrock Technologies and Mikro-Technik GmbH are at the forefront of primary PTFE recycling, providing essential services that help industries extend the lifecycle of PTFE and reduce waste.

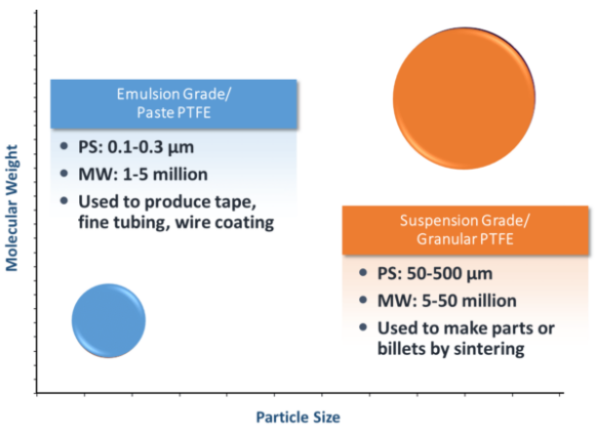

Most PTFE micropowder is made by degrading one of the grades of Natural Prime PTFE, one of the products made, or by-product from the processing of PTFE. These are many grades of PTFE and possible degrees of degradation. Courtesy Shamrock Technologies.

Secondary Recycling: Degrading High Molecular PTFE

In contrast to primary recycling, secondary recycling involves the degradation of high molecular PTFE into micropowder.

Tertiary Recycling: Up-Cycling through Pyrolysis

Tertiary recycling, also known as up-cycling, involves the pyrolysis of PTFE under an inert atmosphere to recover valuable monomers.This process breaks down PTFE into monomers like Tetrafluoroethylene (TFE) and Hexafluoropropylene (HFP). These recovered monomers can then be purified and reused for polymerization, creating new fluoropolymer products. One of the advantages of this process is that it can handle not only homogenous PTFE but also fully fluorinated fluorothermoplastics like PFA and FEP. Additionally, even PTFE compounds with mineral fillers can be recycled through this method. However, up-cycling requires specialized infrastructure and equipment, limiting its accessibility to certain companies. Dyneon GmbH, a subsidiary of 3M, is a leader in tertiary recycling, offering innovative solutions that close the loop on fluoropolymer waste and contribute to a more sustainable production cycle.

Legal and Environmental Considerations

Recycling fluoropolymers must comply with stringent legal and environmental regulations. For instance, the European Waste Directive and the German Closed Substance Cycle Waste Management Act (KrWG) prioritize waste prevention, reuse, recycling, and other recovery methods over disposal. These regulations emphasize the importance of material recovery and the safe disposal of hazardous waste. Additionally, fluoropolymer recycling must adhere to REACH regulations, which require the provision of Safety Data Sheets for all materials. Companies like Aturon GmbH and MINGER Kunststofftechnik AG ensure that their recycling processes meet these standards, minimizing environmental impact and complying with legal requirements.

Fluoropolymers are used widely across many industries, and the restriction of these materials will have implications for many businesses. Courtesy of Mitsubishi Chemical Group – Advanced Materials Division.

The Future of Fluoropolymer Recycling

The future of fluoropolymer recycling lies in the continued development of more efficient and sustainable processes. Current practices, such as primary, secondary, and tertiary recycling, provide a foundation for addressing the challenges associated with fluoropolymer waste. However, there is ongoing discussion about improving these methods to enhance their effectiveness and reduce environmental impact. For instance, advancements in pyrolysis technology could make tertiary recycling more accessible and cost-effective. Additionally, increased collaboration between industry and government could lead to the development of new recycling techniques and infrastructure. By investing in the future of fluoropolymer recycling, industries can contribute to a more sustainable and circular economy.

Recycling fluoropolymers is a complex but necessary process that plays a vital role in promoting environmental sustainability. Primary, secondary, and tertiary recycling processes each offer unique benefits and challenges, but together they form a comprehensive approach to managing fluoropolymer waste. Industries can efficiently repurpose these valuable materials by following legal regulations and investing in innovative recycling technologies.

To read the complete report click here.