Reinforced PVC Composites from E-Waste

PVC Composites reinforced with non-metallic printed circuit boards (PCBs) offer a groundbreaking solution to the escalating e-waste crisis, as it integrates sustainable practices with enhanced material performance.

Electronic waste (e-waste) is the fastest-growing solid waste stream globally, increasing three times faster than the world’s population. Continuous technological advancements, rapid production, high consumption rates, and the short lifespan of electronic equipment are driving this surge. Printed circuit boards (PCBs), which contain metal and non-metal components, are fundamental to electrical and electronic products. Consequently, the generation of waste PCBs is rising rapidly.

You can also read: TERRA is Tackling the Plague of E-waste

The Challenge of E-Waste

The improper management of end-of-life waste electrical and electronic equipment (WEEE) leads to material depletion and environmental pollution. Traditionally, PCB recycling has focused on recovering valuable metals like gold, silver, platinum, and palladium. However, the industry often needs to pay more attention to management of PCB waste from non-metallic PCBs through landfilling and incineration. These practices release toxic substances into the soil, water, and air, negatively impacting the environment.

Innovative E-Waste Recycling

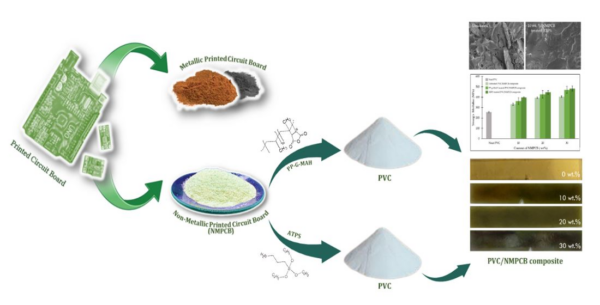

In response to growing public concern, researchers from Bangkok studied the recycling of non-metallic printed circuit boards (NMPCB) as a filler in poly (vinyl chloride) (PVC) composites using two different interfacial agents. This study focuses on utilizing NMPCB in PVC composites to address the dual issues of e-waste reduction and material enhancement. Researchers investigated the effects of two interfacial agents on the properties of PVC/NMPCB composites. These agents were polypropylene grafted maleic anhydride (PP-g-MAH) and ϒ-aminopropyltriethoxy silane (ATPS).

Recycling process of Non-metallic Printed Circuit Boards to create high-performance PVC composites using two different interfacial agents. Courtesy of Development of Environmentally Sustainable Poly (vinyl chloride) Composite from Waste Non-Metallic Printed Circuit Board with Interfacial Agents.

Comparing Interfacial Agents: PP-g-MAH vs. ATPS

Researchers found that interfacial agents significantly improve the compatibility between PVC and non-metallic printed circuit boards (NMPCB). Fourier transform infrared spectroscopy (FTIR) revealed better interactions between PVC and NMPCB when treated with PP-g-MAH and ATPS. However, ATPS proved more effective in enhancing composite properties.

Mechanical and Thermal properties

The study found that the mechanical properties, including Young’s modulus, were significantly improved with the addition of ϒ-aminopropyltriethoxy silane (ATPS). The composite with 30 wt.% NMPCB treated with ATPS exhibited a maximum Young’s modulus of 484 MP. It indicates enhanced stiffness and strength. Additionally, dynamic mechanical analysis showed that ATPS-treated composites had better interfacial adhesion. The improved glass transition temperature (Tg) evidenced this. The Tg shifted to a lower temperature with PP-g-MAH, whereas ATPS led to stronger interfacial adhesion and better thermal stability.

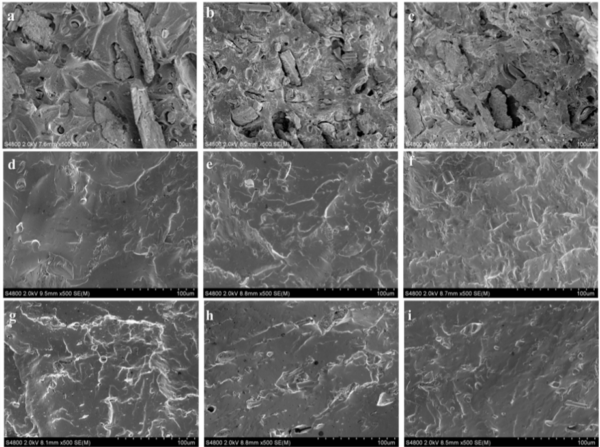

Morphological Analysis

Scanning electron microscopy (SEM) further confirmed that NMPCB particles were more uniformly dispersed in the PVC matrix when treated with ATPS. This dispersion contributes to the improved mechanical properties and overall performance of the composite.

SEM images of PVC/NMPCB composites: (a-c) untreated 10, 20, and 30 wt.% NMPCB; (d-f) NMPCB treated with ATPS at 10, 20, and 30 wt.%; and (g-i) NMPCB treated with PP-g-MAH at 10, 20, and 30 wt.%. These demonstrate superior dispersion in PVC composites with ATPS. Courtesy of Development of Environmentally Sustainable Poly (vinyl chloride) Composite from Waste Non-Metallic Printed Circuit Board with Interfacial Agents.

Boosting Recycling and Functionality

This research has significant implications for waste management and material science. By recycling non-metallic printed circuit boards (NMPCB) into PVC composites, the study offers a sustainable solution to the e-waste problem. It also enhances the properties of PVC. The success of ATPS as an interfacial agent underscores the importance of chemical compatibility in composite materials. Future research could explore other interfacial agents and their effects on different polymer composites. Additionally, collaborating with the electronics industry and the plastics industry could integrate these practices into manufacturing processes, scaling up this recycling method.