Recycling Plastic Mulch Film into Hydrogen and Graphene

Australia’s University of Southern Queensland researchers awarded a grant to recycle plastic mulch film.

The Australian government has provided a $1.8 million grant to further the conversion of difficult-to-recycle plastic mulch film waste into low-carbon hydrogen and graphene. Doing so will help to further its renewable hydrogen goals.

Researchers at the University of Southern Queensland, led by Dr. Xuesen (pronounced Shway-sen) Zeng, are leading the project. They aim to upcycle waste plastic mulch film by converting it into high-value graphene and hydrogen-rich gases. Moreover, the team said integrating graphene will boost the safety performance of Type V hydrogen tanks.

An Australian-UK Partnership

The government’s Department of Climate Change, Energy, the Environment and Water awarded the grant through its Australia-UK Renewable Hydrogen Innovation Partnerships program.

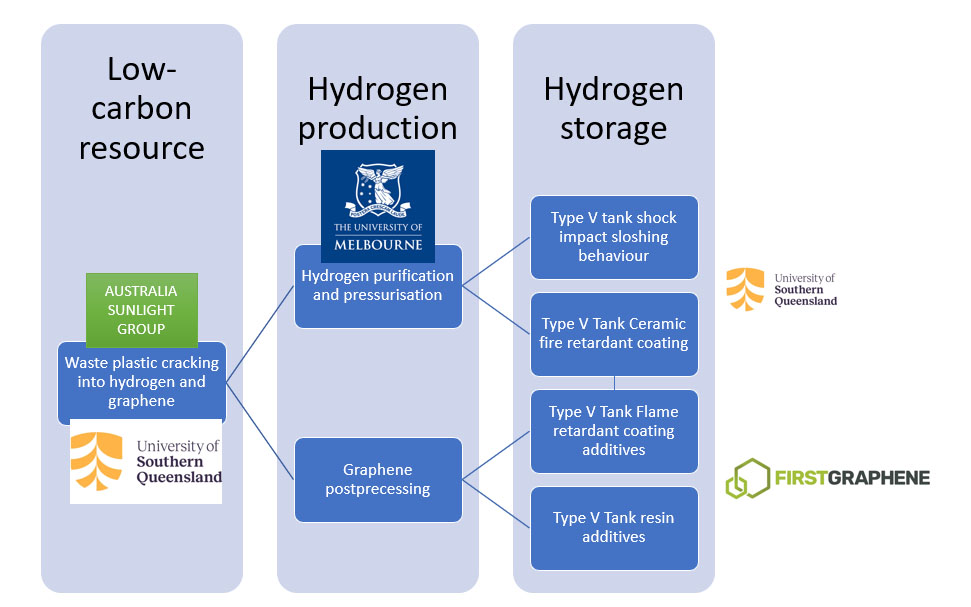

The Graphene Council reports that, together with Australia Sunlight, the University of Melbourne, and First Graphene, one of six U.K. partners in the international collaboration, the team will tackle significant hurdles in producing, purifying, and storing low-carbon hydrogen.

Polyethylene mulches are vital in agriculture. They help to control soil temperature, regulate moisture, prevent weeds, and improve crop yields. Globally, farmers use 4 million tons of plastic mulch annually. Transparency Market Research predicts a 6.1 percent annual increase in the $5.3 billion plastic mulch film market from 2022 to 2031.

The Problem with PE Mulch Film

Australia alone discards more than 40,000 tons, and Europe uses over 85,000 tons of plastic mulch film yearly. However, disposing of used polyethylene plastic mulches poses economic and environmental challenges. It contributes to microplastic pollution in agroecosystems, becoming more toxic over time.

The team’s project proposal notes that existing disposal methods—landfilling, incineration, and recycling—also face issues. While landfilling is common, it raises environmental concerns. Incineration is an option, but recycling is deemed more sustainable. Recycling through chemical or mechanical processes offers potential, but high cleaning costs and low recycled polymer value hinder its economic viability. (This United Nations Environment Programme brief outlines some environmental challenges with plastics in agriculture.)

A Solvent-free Polymer Cracking Method

Zeng says The Flash Joule Heating (FJH) method offers an efficient way to transform plastic waste into graphene and hydrogen. This allows them to sidestep using catalysts and traditional methods.

“This solvent-free process,” he says, “aims to upcycle mulch plastics waste at an estimated cost of $125 per ton. By utilizing FJH, the research team plans to clean and granulate plastic waste, produce conductive plastic granules, and generate hydrogen gas and flash graphene.”

Zeng, a professor of polymer composites with a Ph.D. in mechanical engineering, is working with colleagues Prof. Pingan Song, Dr. Tristan Shelley and Prof. Peter Schubel. Their primary goal of this project involves establishing a cutting-edge pilot plant dedicated to the cracking of agricultural plastic waste.

“The polymer cracking process marks a paradigm shift in waste management strategies,” they assert. This provides “an eco-friendly alternative to conventional disposal methods. By harnessing the potential of agricultural plastic waste, the project aims to contribute significantly to the reduction of carbon emissions and the transition towards a circular economy.”