Pros and Cons of Natural Fiber-Reinforced Plastics in Automotive

The need to produce lightweight, fuel-efficient vehicles that comply with stringent environmental regulations and reduce carbon footprints drives the growing interest in Natural Fiber-Reinforced Plastic (NFRP) composites.

The transportation sector consumes a significant amount of global fuel. It generates substantial carbon emissions, with road, rail, air, and maritime transportation collectively using over fifty-five million barrels of oil daily. As the number of passenger and commercial vehicles doubles by 2040, the sector will increase its contribution to global CO2 emissions, which currently stands at 23%. Road transportation alone produces approximately 72% of these emissions.

You can also read: Perspectives on Electric Vehicles in North America

Vehicle weight is critical to enhance fuel efficiency and curb emissions. Reducing vehicle weight by 10% improves fuel efficiency by 7%, significantly decreasing CO2 emissions. Consequently, the automotive industry has shifted from steel and aluminum to natural fiber-reinforced polymer (NFRP) composites. These materials offer comparable strength and durability at much lower weights.

The Edge of NFRP Composites: Benefits and Applications

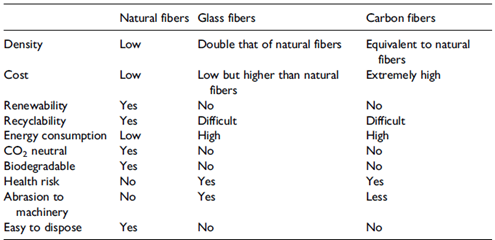

Natural fibers like flax, hemp, jute, and sisal offer benefits, including low cost, minimal environmental impact, and mechanical properties comparable to traditional materials. For example, flax fibers are lighter and consume significantly less energy in production compared to glass fibers, making them an ideal choice for automotive applications. Additionally, NFRP composites provide excellent acoustic, heat, and electrical insulation qualities, enhancing vehicles’ overall performance and sustainability.

Comparison of natural fiber with glass and carbon fibers. Courtesy of Review of natural fiber reinforced engineering plastic composites, their applications in the transportation sector, and processing techniques.

Car manufacturers, such as BMW, Audi, Volkswagen, Daimler Chrysler, and Mercedes, heavily use NFRP composites in their vehicles’ interior and exterior parts. Similarly, international brands like GM, Ford, Volvo, Opel, Renault, and Peugeot are embracing NFRP composites.

Daimler Chrysler is at the forefront, integrating natural fibers like flax, hemp, sisal, and wool into fifty components of the Mercedes-Benz E-Class. Moreover, Daimler employs flax, hemp, sisal, and coconut-reinforced materials in its A, C, E, and S Class models. Despite this, NFRP composites are still primarily composed of virgin commodity plastics or thermosets rather than engineering plastics.

Door panel composite of the Mercedes-Benz S-Class. Courtesy of Review of natural fiber reinforced engineering plastic composites, their applications in the transportation sector, and processing techniques.

Overcoming the Hurdles: Addressing the Disadvantages of NFRP Composites

While natural fiber-reinforced polymer (NFRP) composites offer significant benefits in sustainability, cost-effectiveness, and lightweight properties, they also present challenges. Moisture absorption leads to swelling, reduced strength, and microbial growth, limiting their use in humid or wet conditions. Poor interfacial adhesion between hydrophilic fibers and hydrophobic polymers weakens bonding, compromising durability. Surface treatments and coupling agents can improve adhesion but add complexity and cost to manufacturing, making large-scale applications less attractive.

Furthermore, natural fibers exhibit significant variability in their properties due to differences in species, growing conditions, and processing techniques, which can lead to inconsistencies in the performance of NFRP composites.

You can also read: Applications of plastics in the automotive industry: Current trends and future perspectives

Despite these hurdles, researchers continue enhancing NFRP composites’ performance and applicability. They address challenges using innovative processing techniques and advanced fiber treatments. Consequently, the industry can fully realize NFRP composites’ potential, revolutionizing sustainable manufacturing in transportation.