Electrostatic Discharge Prevention with Conductive Polymer Packaging

Proper Electrostatic Discharge Prevention management is essential for maintaining device performance and extending the operational life of electronic devices.

Electrostatic discharge (ESD) occurs when a sudden flow of electricity happens between two objects with different electrical potentials, typically caused by direct contact or an electrostatic field. In electrical devices, ESD can happen during manufacturing, handling, or operation. When accumulated static electricity discharges, it can damage sensitive components, such as integrated circuits (ICs), transistors, and memory chips. ESD events can lead to latent defects, reduced reliability, and even catastrophic failures.

You can also read: Enhancing Safety in Lithium-Ion Battery Technology

ESD Protection Solutions

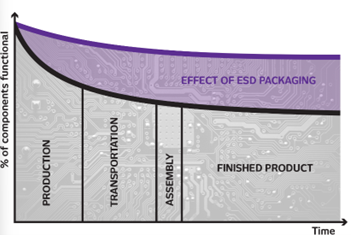

Effect of ESD packaging during the life cycle of electronics. Courtesy of Premix.

Protective measures to mitigate ESD risks include incorporating materials like conductive plastics to safely dissipate static charges. Conductive plastics are engineered by incorporating carbon black into various polymer matrices, such as PP, PE, PS, ABS, and others. This addition of carbon black enhances the conductivity of the plastics, transforming them from insulative materials to effective ESD protectors. These materials are lightweight, corrosion-free, and easier to produce than metal-based alternatives, making them a cost-effective solution for ESD protection.

These materials create a network within the polymer that allows electrons to move freely, providing the necessary pathway for electrical conductivity. Their ability to combine the mechanical properties and processing advantages of plastics with electrical conductivity makes them valuable in industries like electronics, automotive, and aerospace.

Practical Applications and Benefits

The use of conductive plastics extends across numerous practical applications. Companies such as Premix have developed electrically conductive and static dissipative plastic compounds designed to reduce the extent of hidden failures and guarantee a longer operation life for electronic devices. Some of their portfolio include:

- Component Trays and Packaging: Conductive plastics are particularly effective for manufacturing ESD component trays. These trays are essential during the production and transportation phases, as they prevent electrostatic discharge from damaging the components. The materials used ensure that the trays provide consistent conductivity, maintaining their protective qualities even in challenging environments.

PRE-ELEC® PS concentrate is the most cost-efficient raw material solution for ESD component trays. Courtesy of Premix.

- ESD Packaging Foams: For delicate electronic components that require cushioning during shipping and handling, The ideal conductive compounds are EVA and LLDPE. These foams match specific customer needs and processing technologies, providing a combination of shock absorption and ESD protection. This dual functionality helps in reducing the risk of static-induced failures and physical damage.

PRE-ELEC® EVA and LLD compounds and concentrates for foam extrusion are tailor-made to match each customer’s unique process and foaming technology. Courtesy of Premix.

- Heavy-Duty Packaging: In applications requiring robust mechanical properties, such as for heavy or bulky items, the compounds used are conductive ABS and TPU. These materials are co-extruded to produce sheets that offer excellent anti-slip, abrasion, and scratch resistance, in addition to ESD protection. This makes them ideal for protecting surface-sensitive or heavy-duty products during storage and transport.

PRE-ELEC® conductive plastics for boxes, crates, and pallets provide good ESD and mechanical protection to static-sensitive devices and components during assembly and transportation. Courtesy of Premix

Finally, these applications help in preventing hidden failures and extending the operational life of electronic devices by safeguarding them against electrostatic discharge.

The information provided is really good and valuable.

We Need to develop an Anti-static Tray, gram weight: 310-325g, Control 15 tray alternate stacked high 203.0mm±3.0

1. Material: PET transparent (antistatic) Film of Thickness=1.05mm±0.05mm,

2. Point-to-point resistance value: 1.0*10^4 2-1.0*10^9 Ω

3. Ground resistance: 1.0*10^4 2-1.0*10^11Ω

4. Electrostatic value: ±100V

5. Tray incoming material should not be damaged, broken, dust, oil

6. Tray shall meet ROHS standards at the factory

Customers, need value as per the above specification in film with inheritance additive added for antistatic not with coating as they need a shelf life of more than 6 months which they are getting in the current film. Can you please guide/suggest the way forward with – a) What suitable additive to achieve the result 1.0*10^4 2-1.0*10^9 Ω – can you please share supplier contact details? b) Source details of economical test equipment to check point-to-point resistance?

Pls. suggest/guide Best Regards Prashant