Conductive Polymers in Supercapacitors: Innovations and Applications

Conductive polymers (CPs) have emerged as a significant material in the development of supercapacitors due to their unique properties and potential applications in the market.

Supercapacitors, or ultracapacitors, have high power density, rapid charge/discharge rates, and long cycle life, making them suitable for various applications.

Driven by the demand for flexible, lightweight, and durable energy storage solutions, the market for conductive polymer-based supercapacitors is expanding. These supercapacitors find applications in portable electronic devices, wearable technology, electric vehicles, and renewable energy systems. For example, integrating flexible supercapacitors into textiles enables the development of energy-harvesting garments that can power small electronic devices.

Conductive Polymers: The Building Blocks

Conductive polymers, such as polyaniline (PANI), polypyrrole (PPy), and poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT: PSS), possess intrinsic electrical conductivity due to their conjugated backbone structure, which allows for delocalization of π-electrons.

This structure facilitates electronic conduction and supports reversible redox reactions, enabling high pseudocapacitance, which is crucial for energy storage applications and polymers supercapacitors.

Also, these lightweight, flexible polymers can be processed into various forms, enhancing their applicability in flexible and wearable electronics.

Enhancing Conductivity with Composites

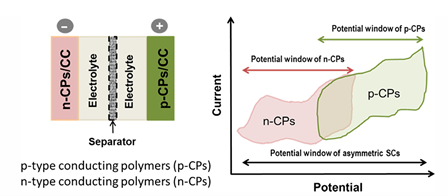

Schematic diagram of asymmetric supercapacitors based on conducting polymers. Taken from Energy Science & Engineering.

Based on their doping process, there are two types of Conductive polymers (CPs): p-type and n-type. These CPs operate within distinct potential ranges determined by their electronic characteristics.

This concept uses the positive potential window of p-type polymers alongside the comparatively negative potential window of n-type derivatives. This approach improves the supercapacitor’s maximum withstanding voltage limits (cell working potential window), enhancing its specific power density.

Enhancing CPs with Composite Materials for Flexible Supercapacitors

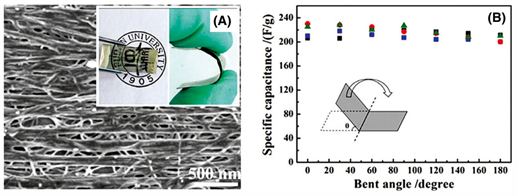

(A) SEM of the PAn/MWCNT (Multi-walled carbon nanotubes) composite (inset photograph showing that the supercapacitor is transparent and flexible). (B) Specific capacitance for a supercapacitor based on the PAn/MWCNT measured at various bent angles. Taken from Energy Science & Engineering.

Despite the advantages of conductive polymers, their poor cycle stability often restricts their practical use. To address this issue, researchers have developed composite electrodes that combine CPs with carbon materials or metal oxides.

This approach effectively enhances the performance and stability of CP-based pseudocapacitors. For instance, notable examples include composites of CPs with carbon nanotubes (CNTs), graphene oxides (GO), carbon cloth (CC), and metal oxides such as MnO₂, Co₃O₄, and RuO₂. Furthermore, these composites demonstrate highly stable supercapacitive performance due to the improved conductivity and redox behavior provided by integrating CNTs, GO, or metal oxides. Consequently, such advancements in composite materials are crucial for developing flexible supercapacitors that meet the demands of modern electronic devices. Overall, they offer a reliable and efficient energy storage solution.

Industry Applications and Challenges

Driven by the demand for flexible electronics, CP-based supercapacitors will capture a significant market share from traditional Li-ion batteries within the next decade. Moreover, boasting high Faradaic capacitance, flexibility, conductivity, and ease of fabrication, these supercapacitors are ideal for thin, wearable devices integrated into clothing and other portable applications.

Supercapacitors Market Outlook (2023 to 2033). See the full report at Future Market Insights.

Despite these promising advancements, challenges remain. Researchers focus on improving mechanical stability with flexible current collectors, enhancing cycle stability through composites with carbon nanomaterials or self-healing polymers, and integrating nanoscale active materials with high power characteristics.

Additionally, innovations aim to improve charge transport and reduce resistance by directly synthesizing active materials on current collectors without binders. Future developments include hybrid asymmetric supercapacitors with p-type and n-type CPs, though n-type CPs currently lag in quality.