Hybridizing Epoxy Composites with Egg Shell Powder

Recent advances have shown that natural and waste-derived fillers, like eggshell powder (ESP), can greatly enhance the properties of composite materials.

Institutions across India studied the synergistic effects of natural fiber composites with bio-fillers. B. Ashok Kumar et al. conducted research incorporating jute fibers and ESP into an epoxy matrix. They added ESP in varying concentrations (3%, 6%, 9%, and 12% by weight), which enabled them to evaluate its influence on the composite’s mechanical strength, flexibility, and hardness.

You can also read: Harnessing Hemp for Automotive Composites

Ingredients used (a) Resin and hardener (b) Untreated jute fiber (c) Powdered egg shell. Courtesy of Study on the mechanical properties of a hybrid polymer composite using eggshell powder based bio-filler.

Enhanced Mechanical Properties

The study highlighted substantial improvements in the mechanical properties of the hybrid composites with the inclusion of ESP:

- Tensile Strength: The optimal addition of 9% ESP led to a 73.83% increase in tensile strength compared to composites reinforced only with jute fibers.

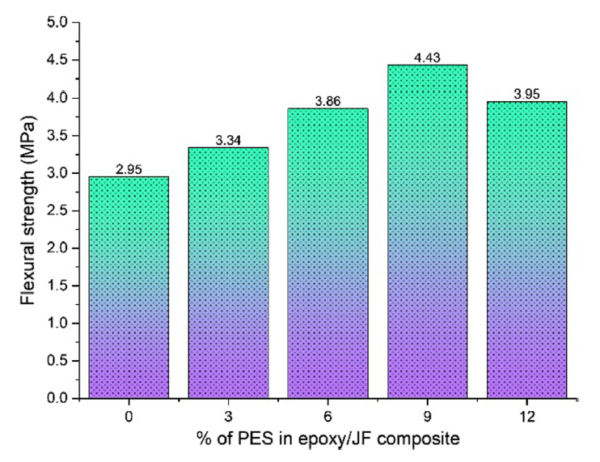

- Flexural Strength: Similarly, incorporating 9% ESP improved flexural strength by 50.17%.

- Shore D Hardness: The hardness of the composites also saw an increase of 21.43% with 9% ESP.

The mechanical enhancements plateaued beyond a 9% inclusion rate of ESP, indicating an optimal filler content that maximizes mechanical benefits while preserving the integrity of the epoxy matrix.

Flexural behavior of the epoxy/JF/PES composite specimens. Courtesy of Study on the mechanical properties of a hybrid polymer composite using eggshell powder based bio-filler.

An Eco-Friendly Alternative

Integrating ESP beneficially utilizes waste materials and enhances the mechanical properties of composites. Additionally, improvements in tensile strength, flexibility, and hardness result from better stress distribution and stronger bonding at the ESP-epoxy interface. Consequently, these findings position ESP as a cost-effective and eco-friendly alternative to traditional fillers in polymer composites.

Outlook on Bio-fillers and ESP

Eggshell powder has proven to enhance the mechanical properties of jute fiber-reinforced epoxy composites, making them more suitable for applications requiring high strength and durability. The optimal concentration of ESP offers a balance between improved mechanical properties and material integrity. This presents a new avenue for the use of bio-fillers in composite manufacturing.

Utilizing ESP not only addresses waste management challenges but also enhances the performance of bio-based composites. This opens the way for more sustainable material practices in industries such as automotive and construction.