Sheets vs Film: Key Distinctions

The terms “film” and “sheet” often lead to confusion within and outside the industry, as they are sometimes used interchangeably. While both refer to thin, flat materials, they possess distinct characteristics and applications.

To begin with, thermoplastic versatility allows both sheets and films to be formed, with these formats representing the largest share of global plastic production. Several methods, including extrusion, calendering, and casting, are employed to manufacture films and sheets. The chosen technique depends primarily on the desired properties of the final product, the inherent characteristics of the chosen plastic, and cost considerations, often influenced by production volume.

You can also read: Essentials of Plastic Material Selection: Key Steps Simplified

Classifying film and sheet based on thickness offers a helpful starting point:

Specifically, differences between films and sheets are related to their technical characteristics.

- Films: According to ASTM Standard Terminology Relating to Plastics (D883-23), a film typically measures less than 0.25 mm (0.01 inches).

- Sheets: Exceed 0.25 mm in thickness, with some reaching several centimeters. The thickness range of the extruded sheet is normally between 0.010 and 3 in.

Industry-specific variations are common in terminology. Various groups within different industries such as plastics, packaging, aluminum, clothing, etc., often create their thickness definitions and terminology based on customer preferences or established practices. In some industries, 0.004 inches (0.10 mm) serves as the dividing line between film and sheet.

Markets and Applications

Broadly, three major markets exist for films:

- Packaging: Encompasses applications like food wraps, bags, and other packaging solutions.

- Industrial: Includes diverse uses such as tapes, photographic film, and various industrial applications.

- Soft goods: This category covers items like raincoats, shower curtains, and upholstery materials.

In the case of sheets, thinner gauges find their primary application in thermoformed food packaging, such as trays and blisters. These offer superior rigidity and dimensional stability, making them ideal for holding their shape and protecting contents. Beyond food packaging, thinner sheets find diverse uses in:

- Stationery and office products: Creating lightweight, durable folders, dividers, and presentation materials.

- Tanks, ducting, and industrial applications: Offering a combination of strength, formability, and chemical resistance for various industrial needs.

Manufacturing Processes of Sheets and Films

Film production utilizes two primary methodologies: tubular blowing and flat extrusion. Each boasts distinct advantages and disadvantages, influencing the optimal choice for specific applications.

Blown Film Production: Process Overview

Blowing plastic on a machine into a roll for the production of plastic bags.

Blown film production, a prevalent method for making films, entails extruding a thick tube that is then expanded into a thin film through air or water quenching. The resulting film exhibits molecular orientation predominantly in the machine direction (MD), with variations based on process parameters and material characteristics.

Flat Film Extrusion: Casting Techniques

Flat film extrusion, or cast film production, uses chill rolls or water quenching to cool and shape molten plastic into thin, uniform sheets. Unlike blown films, flat films undergo minimal orientation, resulting in superior clarity and surface finish.

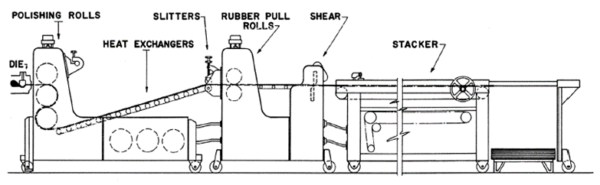

Sheet production predominantly relies on extrusion with polished, stacked rolls. This method, sometimes employing an air knife, creates sheets suitable for various applications. Approximately 60% of sheets undergo thermoforming, shaping them into specific designs. Alternatively, fabrication techniques like blanking, punching, machining, and welding offer greater flexibility for intricate shapes.

Schematic of sheet line processing elastomer. Courtesy of Plastics Technology Handbook. Volume 1.

Certain plastics, such as polypropylene sheets, can incorporate hinges or creases using a cold coining technique. Key properties of sheets include:

- High strength and rigidity-to-thickness ratio: Ideal for structural applications.

- Toughness: Resists impact and wear.

- Moisture and sterilization resistance: Suitable for diverse environments.

- Effective moisture barrier: Protects contents from moisture ingress.

- Chemical resistance: Compatible with various chemicals.

- Non-toxicity: Safe for food and medical applications (where applicable).

As a conclusion, the technical disparities between sheets and films underscore their distinct manufacturing processes, properties, and applications. Whether it’s the strength and rigidity of extruded sheets or the versatility of blown films, understanding these differences is crucial for stakeholders seeking optimal material solutions. As technology evolves, so will the capabilities and applications of sheet and film extrusion, shaping the future of plastic manufacturing globally.