Bio-Polyethylene: When Performance Meets Sustainability

The plastics market demands sustainable alternatives to conventional fossil-based plastics.

Bio-Polyethylene emerges as a promising solution, offering environmental advantages and maintaining performance.

You can also read: Advancements in LDPE Synthesis and Recycling

Driving Sustainable Markets Forward

Considering the ongoing concerns surrounding the environmental impact of plastic production and disposal, it is crucial to examine the current landscape of plastic production. Nowadays, it is estimated that fossil-based plastics represent around 97% of worldwide production. Although there have been countless efforts to promote more sustainable solutions, currently only 1.5% of global plastic production corresponds to biologically sourced plastics. Among plastics, polyethylene has become one of the most widely used fossil-origin polymers globally, representing nearly 27% of global plastic production. The production of polyethylene from fossil fuels involves complex processes that contribute to greenhouse gas emissions and air pollution.

Countries around the world have set the challenge of gradually replacing traditional polymers produced from fossil sources with the corresponding polymers obtained from renewable sources.

Bio-polyethylene (Bio-PE) stands out as one of the most successful cases in recent years, with an expected Compound Annual Growth Rate (CAGR) of 15% from 2023 to 2030. The market’s growing demand for more sustainable alternatives that maintain product performance drives this growth.

A Possible Alternative to Conventional PE

Bio-PE and conventional PE share the same monomer polymerization. However, the key difference lies in monomer production. Bio-PE utilizes bioethanol from the glucose in sugarcane, which is one of the most used biomass sources for this application. This process significantly reduces the carbon footprint compared to conventional PE production.

As detailed in the review article published in the journal, Polymers, titled “Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly(ethylene terephthalate) (Bio-PET): Recent Developments in Bio-Based Polymers Analogous to Petroleum-Derived Ones for Packaging and Engineering Applications”. The authors noted that bio-based and fossil-based polyethylene possess comparable chemical, physical, and mechanical properties, making them adaptable for various plastics conversion processes. Both types of materials are subject to identical alterations in chemical structures. Furthermore, it’s feasible to adjust the long-chain and short-chain branches, which are characteristic features across different polyethylene variants.

Polyethylene Producers Embrace Sustainability

Braskem’s portfolio now offers over 20 bio-PE, certified by ASTM 6866, with renewable content ranging from 80 to 100%. These materials find applications in both flexible and rigid packaging for the food and chemical industries. Additionally, DOW Chemical, a leading global polyethylene producer, is advancing bio-based polyolefin elastomers (POEs) for hot melt adhesives in food and detergent packaging, aiming to reduce carbon footprint. Furthermore, DOW plans to introduce bio-based ionomers for sustainable caps in the fragrance industry, leveraging their transparency and glass-like properties. These initiatives mark a notable shift towards sustainability in the plastics industry, where performance and environmental considerations align.

Reducing Environmental Impact

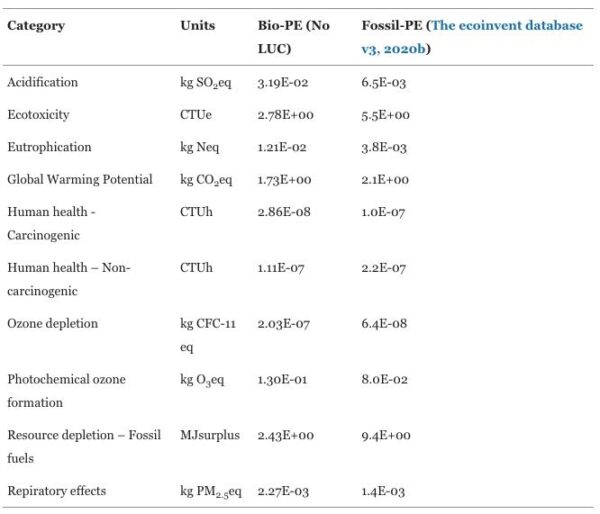

Regarding sustainability, bio-PE seems to be a sustainable alternative to conventional PE. In the scientific study ”Is sugarcane-based polyethylene a good alternative to fight climate change?” Researchers found that bio-PE has a lower Global Warming Potential (GWP) than fossil-PE and outperforms in environmental indicators. With the exception in acidification and eutrophication areas. They drew two important conclusions from the study. First, the decision to choose between bio-PE and fossil-PE should depend on the environmental indicator most relevant to the specific application. Second, the sugarcane cultivation method determines the environmental impact of bio-PE. The study found that the GWP of the sugarcane planted in lands that previously were pastures is lower than the sugarcane from forests. Land-use change emerges as a critical variable in defining the environmental impact of bio-PE.

Environmental impacts of high-density bio-PE (No LUC) and fossil-PE. Courtesy of Is sugarcane-based polyethylene a good alternative to fight climate change?

Regarding waste management, bio-PE can be reused, recycled mechanically, and used for energy recovery. Moreover, bio-PE produced can easily be recycled with existing PE streams, contributing to higher recycling rates and circular economy.

Lastly, while bio-PE holds promise in terms of sustainability, it encounters regulatory and commercial hurdles. The absence of supportive regulations in many countries and the limited production capacity impede its widespread adoption. Overcoming these challenges demands concerted efforts from industry stakeholders, policymakers, and producers to realize the full potential of bio-based plastics in building a more sustainable future.