Enzyme from Laundry Detergent Transforms Single-Use Plastics in Just 24 Hours

Innovative Chemical Recycling for Single-Use Bioplastics

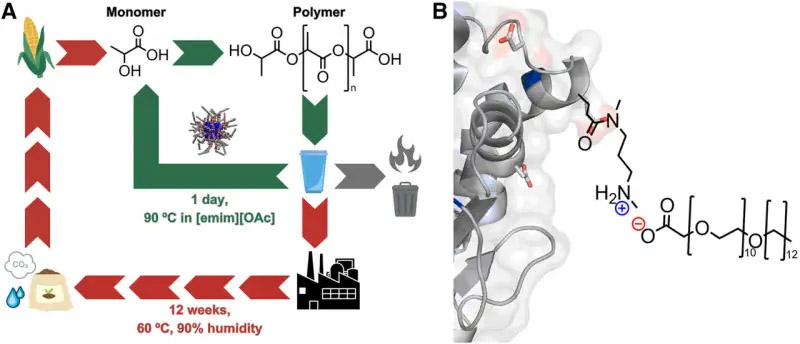

Scientists at King’s College London have unveiled a groundbreaking method for recycling single-use bioplastics, commonly found in disposable items like coffee cups and food containers. Published in Cell Reports Physical Science, the chemical recycling approach utilizes enzymes akin to those in biological laundry detergents to swiftly break down landfill-bound bioplastics within just 24 hours.

This pioneering solution targets the rapid conversion of bioplastic polylactic acid (PLA), achieving full degradation within a day—84 times faster than industrial composting. Further, at 90°C in an additional 24 hours, the bioplastics transform into chemical building blocks or monomers. These monomers can be used to create high-quality reusable plastic, offering a sustainable alternative.

An estimated 68 million tons of plastics ended up in natural environments in 2023 alone. Traditional plastic production outpaces sustainable disposal methods, contributing to pollution and environmental degradation. While bioplastics are considered more eco-friendly, existing production methods are costly and compete with food-based agriculture. Mechanical recycling proves inefficient, generating CO2 and failing to produce high-quality reusable materials, often leading to landfill use.

The Potential for a Circular Economy

King’s College London’s research provides a breakthrough in single-use bioplastic recyclability, potentially transforming plastic production. This efficient, scalable, and sustainable blueprint offers a path to a circular economy. It has the power to combat the dominance of fossil-based plastics and reduce the massive volume of plastic waste entering landfills and natural environments.

Dr. Alex Brogan, Lecturer in Chemistry at King’s College London, emphasizes the transformative nature of harnessing biology for sustainable solutions through chemistry. The research, initially inspired by challenges in medical product bioplastics, opens avenues for rethinking waste as a resource, moving away from non-renewable sources and towards a sustainable future.

Extending Research for Broader Impact

The scientists at King’s College London are expanding their research to enhance the recycling of commonly used plastics, such as those in single-use water bottles, film and sheet packaging, and clothing. This commitment positions their work as a crucial step in waste management, offering technologies to recycle bioplastics at a quality comparable to virgin products—a monumental stride in plastics recycling.