Agro-Waste to Biopolymers: Upcycling with Bio-Additives

Have you considered the potential of transforming household fruit and vegetable waste into 3D printing filaments? The BARBARA project has successfully developed biopolymers, enhanced with bio-additives derived from food waste, for the additive manufacturing of components.

The BARBARA project, supported by CBE JU, was developed to valorize waste from the agri-food industry and accelerate the bio-circular economy in Europe. With these goals in mind, they obtained polysaccharides from corn and new bio-additives from lemon, broccoli, pomegranate, and almond peels. Subsequently, from these bio-compounds, they produced bioplastics for fused filament fabrication (FFF) processes.

You can also read: PepsiCo Sees Biopolymers as Key to Sustainability in Flexible Packaging

Biopolymers for Fused Filament Fabrication Processes

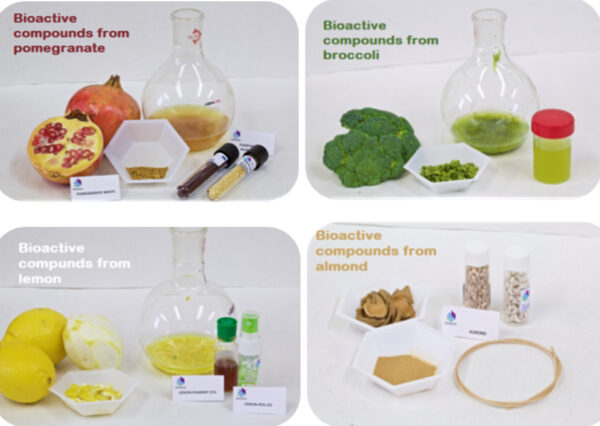

Bio-additive compounds from the pomegranate, broccoli, lemon, and almond peel.Courtesy of BARBARA Project

BARBARA Project developed bioplastics for 3D printing manufacturing of automotive and construction parts in 4 stages:

1. Agro-industrial waste acquisition

First, the Spanish company FECOAM stored and delivered agro-industrial waste to the University of Alicante (UA). The latter was responsible for the investigative laboratory-level part of the project.

2. Extraction and Modification of Bio-Based Components

The University of Alicante used two processes for extracting polysaccharides from corn and bio-additives from other foods. The first method, known as subcritical water extraction (SWE), and the second method, microwave-assisted extraction (MAE), was implemented solely for obtaining the additives

The polysaccharides obtained in the process were compatibilized by green functionalization techniques with other biopolymers such as polyamides and polyesters to enhance thermo-mechanical properties and moisture resistance.

The extracted bio-additives included lemon oil and yellow pigment, pomegranate pigments and antibacterial biomordant, broccoli green pigment, and almond peel antimicrobial extract and reinforcing additive. It’s worth noting that the company CELABOR encapsulated the additives (except pigments) in nano clays to increase stability and sustained release.

3. Formulations Processing

Once the two main components of the bioplastic were ready, multiple formulations were developed to find the best composition of bioplastics with bio-additives. The selected material would then be processed for 3D printing filament production.

4. Validation

In the validation process, CRF and ACCIONA manufactured and tested three prototypes: a fascia and interior door trim for the automotive sector, and a mold for the construction sector

Pioneering a New Era for Upcycling

At the conclusion of the BARBARA project, researchers obtained eight materials, demonstrating that biopolymers with bio-additives can replace non-renewable source polymers in FFF applications for the automotive and construction sectors

New projects in the industry must seek novel ways to chemically transform biomass into biopolymers and bio-additives for industries such as pharmaceuticals, food packaging, engineering, and medicine. BARBARA’s project have proved the viability of the development of this kind of materials