96-Cavity Mold Conversion: A Seamless and Beneficial Transition

MHT wowed the PET-preform industry by cutting cycle time by three seconds in a 96-cavity mold conversion for Deltaplast.

This remarkable feat, transitioning from Engel to Netstal after 6.5 million cycles, showcases MHT’s adaptability.

You can also read: Sidel Unveils High-Speed PET Bottle Blow Molding Machine, Husky Earns PLASTICS’ bioplastics innovation award for its novel hot-runner system, Yankang Plastic Machinery Blow Molds Massive HDPE Water Tanks

Adapting PET-Preform Precision

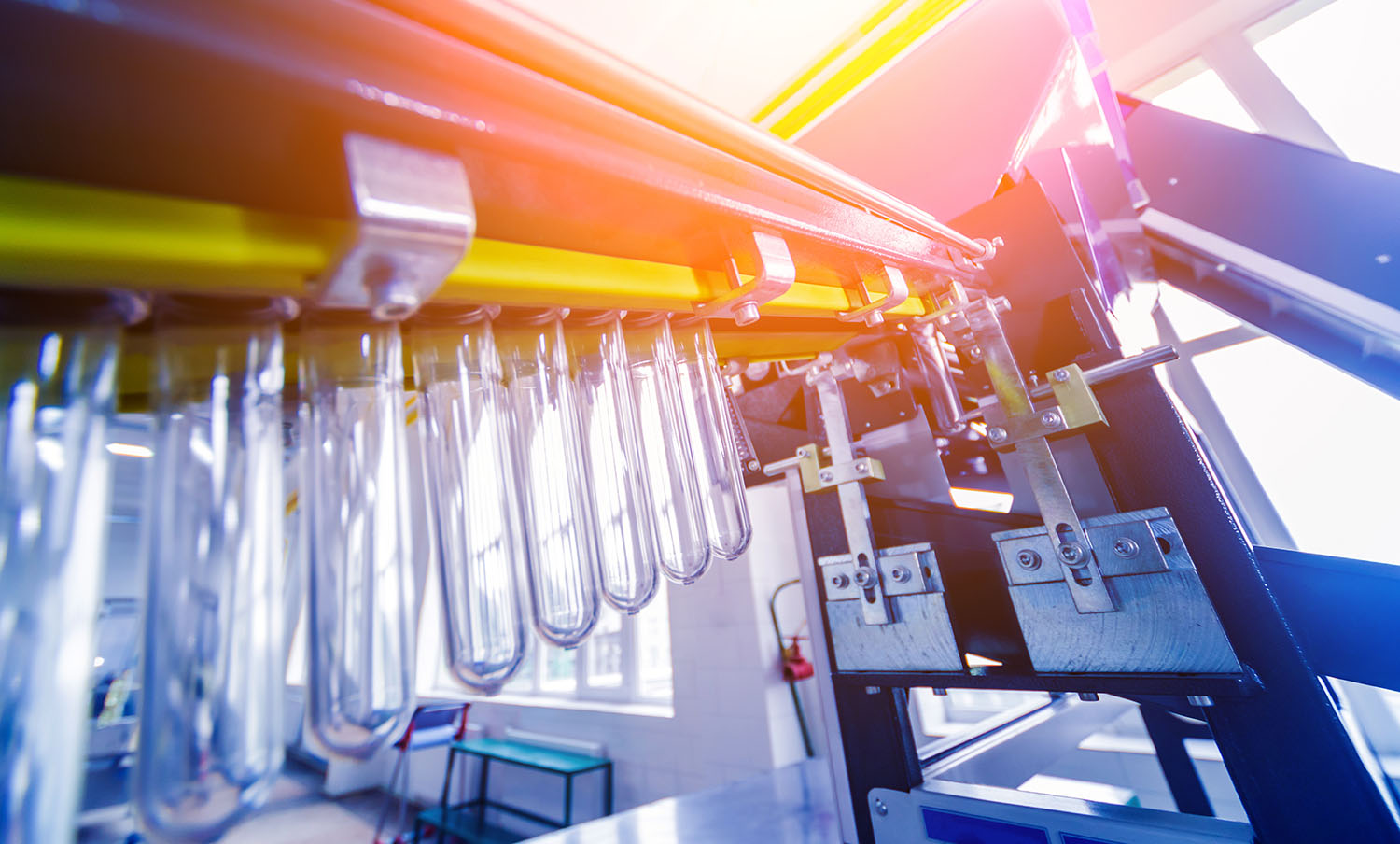

MHT Mold & Hotrunner Technology AG showcased adaptability in meeting rising demands for PET-preform production. The company successfully converted a 96-cavity mold from an Engel system to Netstal for Deltaplast, a Hungarian preform producer. Remarkably, this conversion occurred after 6.5 million cycles and multiple refurbishments, resulting in a noteworthy three-second reduction in cycle time.

MHT Mold & Hotrunner Technology AG wowed the PET-preform industry by cutting cycle time by three seconds in a 96-cavity tool conversion.

With an increasing need for high-quality preforms, manufacturers like Deltaplast are constantly exploring ways to optimize their production processes. Recently, Deltaplast’s acquisition of a Netstal PETline 4000 Side Entry prompted the decision to convert the existing mold, previously running on an Engel macPET 330 since 2015. Deltaplast collaborated with MHT to address a complex project, taking advantage MHT’s established expertise in high cavity preform molds for various PET systems.

Innovating Efficiency Seamlessly

MHT’s adaptability is evident not only in its mold conversion capabilities but also in its diverse range of adapter kits. These kits enable manufacturers to easily convert molds between machine generations, brands, or clamping force sizes. Additionally, MHT’s innovative “upgrade kits” can, in certain cases, increase cavity count to meet the escalating demands of production.

In this conversion, MHT employed an adapter kit for the cold side and created a new hot runner. Notably, MHT manufactures its hot runners, ensuring seamless integration tailored to the specific needs of the production process. The update of the pre-mold and post-mold cooling system, featuring the patented “coolMax” cooling solution, optimizing not just the cycle time but the entire production workflow.

In an industry where efficiency is paramount, MHT’s successful conversion for Deltaplast underscores the vital role that mold adaptation plays in addressing the evolving demands of the sector. As manufacturers strive to enhance efficiency and meet heightened production requirements, MHT’s expertise emerges as a valuable resource, offering solutions that extend beyond traditional mold functionalities to boost overall productivity.

To read more: Converting 96 Cavity Mold Optimizing Cycle Time