Plastic for 3D Printing: Filaments vs Pellets

Plastics play a pivotal role in additive manufacturing, catering to diverse needs in various sectors. This article delves into the world of two polymer forms—filaments and pellets—exploring their characteristics, applications, and compatibility with 3D printing processes. Focusing solely on plastics, we revisit the definitions of pellets and filaments. Pellets, small meltable balls, are vital in the chemical industry and find application in additive manufacturing. Filaments, thermoplastics formed by mixing pellets with additives, require extrusion to achieve a tube-like structure. This dedicated exploration provides insights into manufacturers, compatibility, and costs of these materials, serving as a valuable resource for professionals in the plastics engineering field.

Characteristics and Properties of Filaments and Pellets

In the expansive realm of plastics engineering, understanding the characteristics and properties of filaments and pellets is crucial. Plastics, in various forms like liquids, powders, or pellets, undergo shaping processes like molding, injection, thermoforming, and extrusion to produce diverse parts. Industrial plastic pellets, also known as nurdles, offer a wide array of properties based on their chemical composition and are used in traditional manufacturing methods like injection molding. Leveraging pellets in 3D printing provides the advantage of using qualified materials seamlessly across different manufacturing technologies.

On the other hand, filaments involve a more intricate manufacturing process, converting plastic pellets into extrudable tubes. This process includes pellet drying, melting, extrusion, and cooling, resulting in spooled filaments for 3D printing. While filaments allow for a broader range of compatible plastics, including PLA, ABS, elastomers, and high-performance polymers like PEEK or PEI, they require an additional step for material qualification due to the introduction of additives during the transformation process.

Choosing between pellet and filament 3D printing depends on specific project requirements. Pellet 3D printing offers versatility and ease of material transition between additive and traditional manufacturing methods. Filament 3D printing, while involving a more elaborate process, provides a diverse range of polymer options for customized properties, catering to transparency, mechanical strength, or other specific needs. Plastics engineers navigating these choices must consider the chemical composition, transformation challenges, and desired material characteristics for optimal results in additive manufacturing.

Compatible 3D Printing Processes

In the realm of plastics engineering, the choice between plastic pellets and filaments in 3D printing revolves around the extrusion process, specifically Fused Deposition Modeling (FDM/FFF) for filaments and Fused Granulate Fabrication (FGF) for pellets. The fundamental principle involves heating the plastic material and layer-by-layer deposition on a platen to craft the final object.

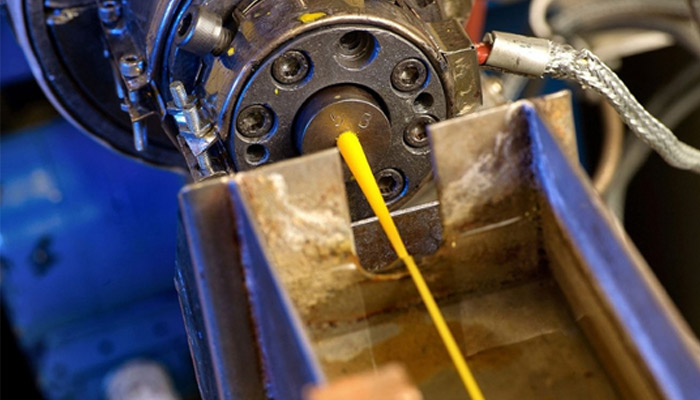

The extrusion system for plastic pellets is different from that for filaments. Courtesy of Pollen AM

Filaments utilize an extruder with a stepper motor and toothed wheel to manage filament movement. The heated material passes through a nozzle, depositing filament on the print bed. Material-specific components, such as brass or copper nozzles, a heated chamber, or a heated plate, influence the choice of machine and printing parameters.

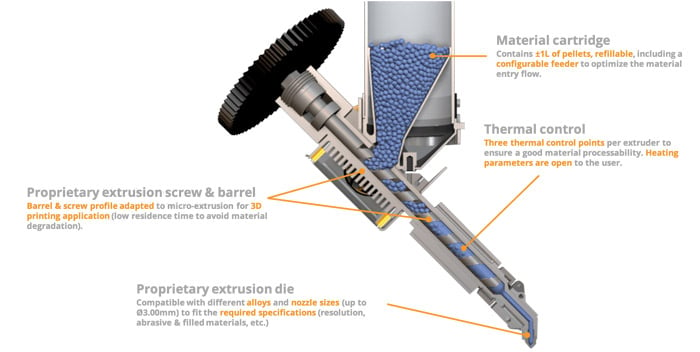

Pellets, in the FGF extrusion process, involve a hopper system absorbing plastic beads and conveying them to the melting zone. The softened pellets are then ejected through a nozzle, depositing material layer by layer on the printing plate. Pellet extrusion systems, often integrated into robotic arms, offer increased printing surface and flexibility, making them suitable for large-format parts with higher deposition speeds and volumes.

While pellet 3D printing excels in efficiency for large parts, it sacrifices precision and resolution compared to filament printing. Pellet printers lack the ability to shrink material flow, potentially leading to excessive plastic flow through the nozzle. For intricate and detailed designs, 3D filament printing proves more suitable, allowing for the creation of complex parts with precision and accuracy. The choice between these approaches hinges on the project’s specific requirements, balancing factors like size, intricacy, and material characteristics in the context of the extrusion method chosen.

Filament and Pellet Applications in 3D Printing

In the realm of plastics engineering, the applications of 3D printing with pellets or filaments share common ground, including prototyping, tooling, and finished parts across various industries. Filaments, known for versatility, are ideal for creating modest-sized parts with intricate details. They find extensive use in rapid prototyping, offering properties like fire resistance, biocompatibility, and carbon fiber reinforcement. On the other hand, pellets provide a unique advantage by enabling the formulation of tailor-made blends through the mixing of different plastics. This versatility is particularly valuable in the healthcare sector for crafting biocompatible materials, customized prostheses, and implants.

Pellets’ applications extend to the automotive sector, where they expedite the development of customized parts such as dashboard elements and engine covers, reducing costs in the process. They are also sought after in the design sector for creating larger furniture and decorative items. Notably, pellets can be produced from recycled materials, aligning with the principles of the circular economy. Importantly, the use of pellets in additive manufacturing offers efficiency in material prototyping, as the same raw material can seamlessly transition from 3D printing to injection molding without the need for additional certification stages. This streamlined approach significantly saves time for manufacturers.

The Cost of Materials

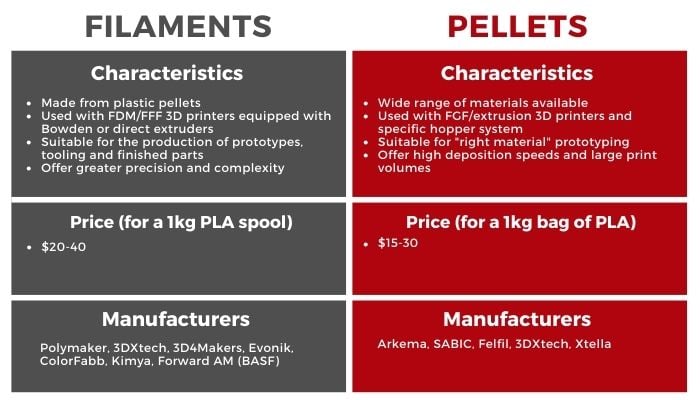

Filaments, popular for their affordability and accessibility in spool form, are widely available on the market. A standard 750-gram spool, particularly for PLA, a prevalent material, ranges from $20 to $30. However, specialized filaments like flexible or composite may incur higher costs, ranging from $30 to $50 per spool. For those frequently printing large objects, filament expenses can accumulate quickly.

In contrast, pellets, sold in multi-kilogram bags, allow bulk purchasing, representing a higher initial investment ranging from $50 to $100 or more. Despite the upfront cost, pellets often offer a financial advantage over filaments. The lower cost per kilo of pellets stems from the less complex transformation process compared to filaments. While initial pellet costs may seem higher due to bulk purchase, they can be more economical in the long run for regular 3D printing users, contingent on individual needs and budget considerations.

Filament and Pellet Manufacturers on the Market

In the expansive realm of 3D printing, numerous manufacturers contribute to the market’s growth, offering diverse filaments and pellets. Filaments, appreciated for their user-friendly nature, are supplied by notable companies like Polymaker, 3DXtech, 3D4Makers, Nanovia, ColorFabb, and Kimya, providing high-quality options from PLA to PETG and ABS. Major chemical companies, such as BASF and Evonik, have also developed their filament brands.

For plastic pellets, key players include chemical groups like Arkema and SABIC, along with manufacturers like Felfil, 3DXtech, and Xtellar. Some specialize in producing pellets from recycled waste, such as re3D, while others like KIMYA focus on both pellet and filament production.

In the realm of compatible machines, the market is diverse. For filaments, established players like Stratasys, UltiMaker, and Zortrax coexist with emerging office, professional, and industrial solutions. On the pellet front, notable manufacturers include Arburg and Pollen AM, alongside 3D Systems, which acquired Titan Robotics in 2022, and AIM3D. This list is not exhaustive, highlighting the dynamic landscape of 3D printing technologies.

In conclusion, both types of plastic offer production advantages well suited to different manufacturing situations. Make sure you use the right material to maximize the efficiency of your additive manufacturing process!