Solvay at Fakuma: High-Performance e-Mobility Resins and Increased Circularity

New resins include two Ryton PPS grades and one long-glass-fiber PPA for EVs

Brussels-based Solvay SA is planning a busy Fakuma trade fair this week in Germany, introducing various high-performance resins, including two Ryton PPS grades and a new long-glass-fiber PPA material for battery applications. It also will be showcasing its sustainability efforts, including the roll-out of its Echo portfolio that encompasses materials meant to advance a carbon-neutral future.

Solvay created its Supreme polymer portfolio as a new brand for products designed specifically for e-mobility, offering enhanced performance. The two new additions are Ryton Supreme HV and HF grades of polyphenylene sulfide (PPS) –– both high-flow and high-voltage polymers. These join an existing Amodel-brand polyphthalamide (PPA) under the Supreme banner. (See video.)

“For the moment we have [these] three grades in our portfolio, with the potential to expand with other polymers such as LCP, PARA or PEEK,” said Nicolas Batailley, marketing manager for transportation, in an email interview.

“Our first target is e-mobility and charging infrastructure, including superchargers and the grid. But,” he said, “our colleagues in charge of the electronics and smart device markets are also interested in the potential application of these products.” The company developed Ryton Supreme HF in Europe and Ryton Supreme HV in North America.

“The performance of these products comes from the combination of specialty resins developed by our scientists with high-performance fillers that require specific compounding expertise,” Batailley said. “In short, we need to combine polymer science –– formulation and operational excellence.”

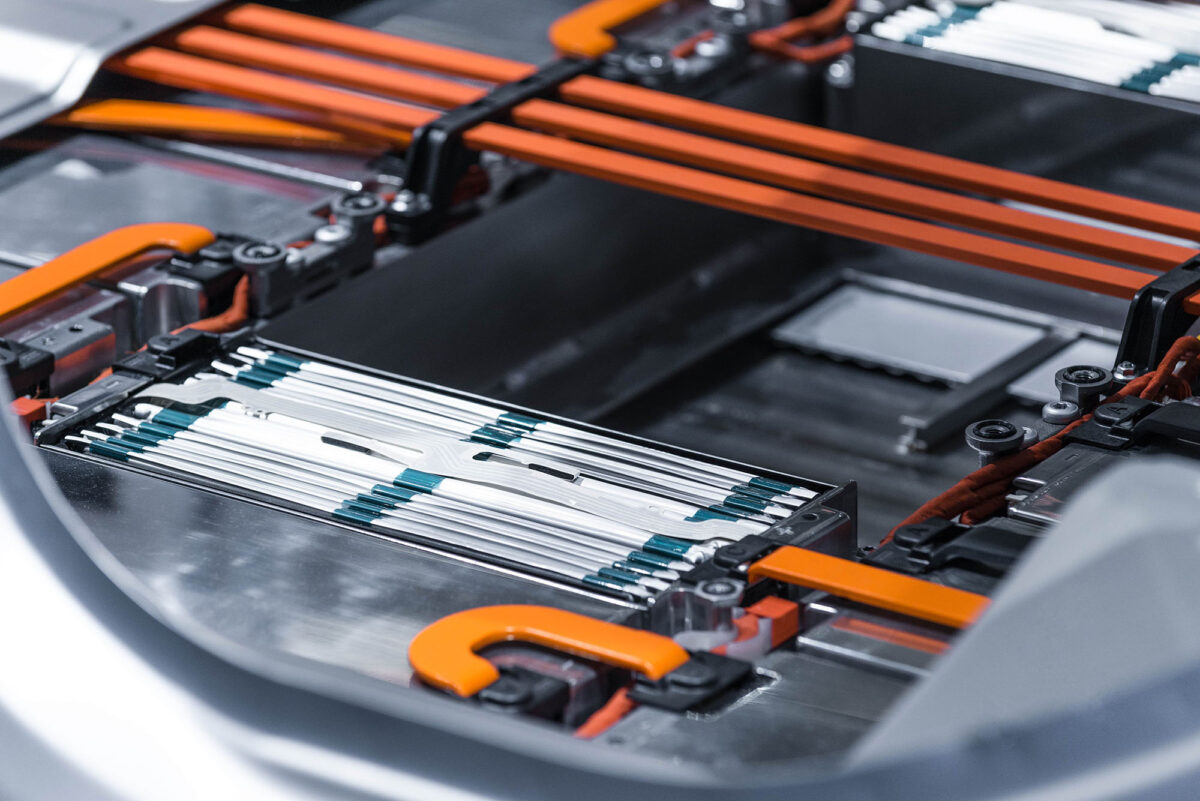

Offering thermal runaway protection

Solvay is targeting various high-performance materials at EV battery applications. Courtesy of Solvay

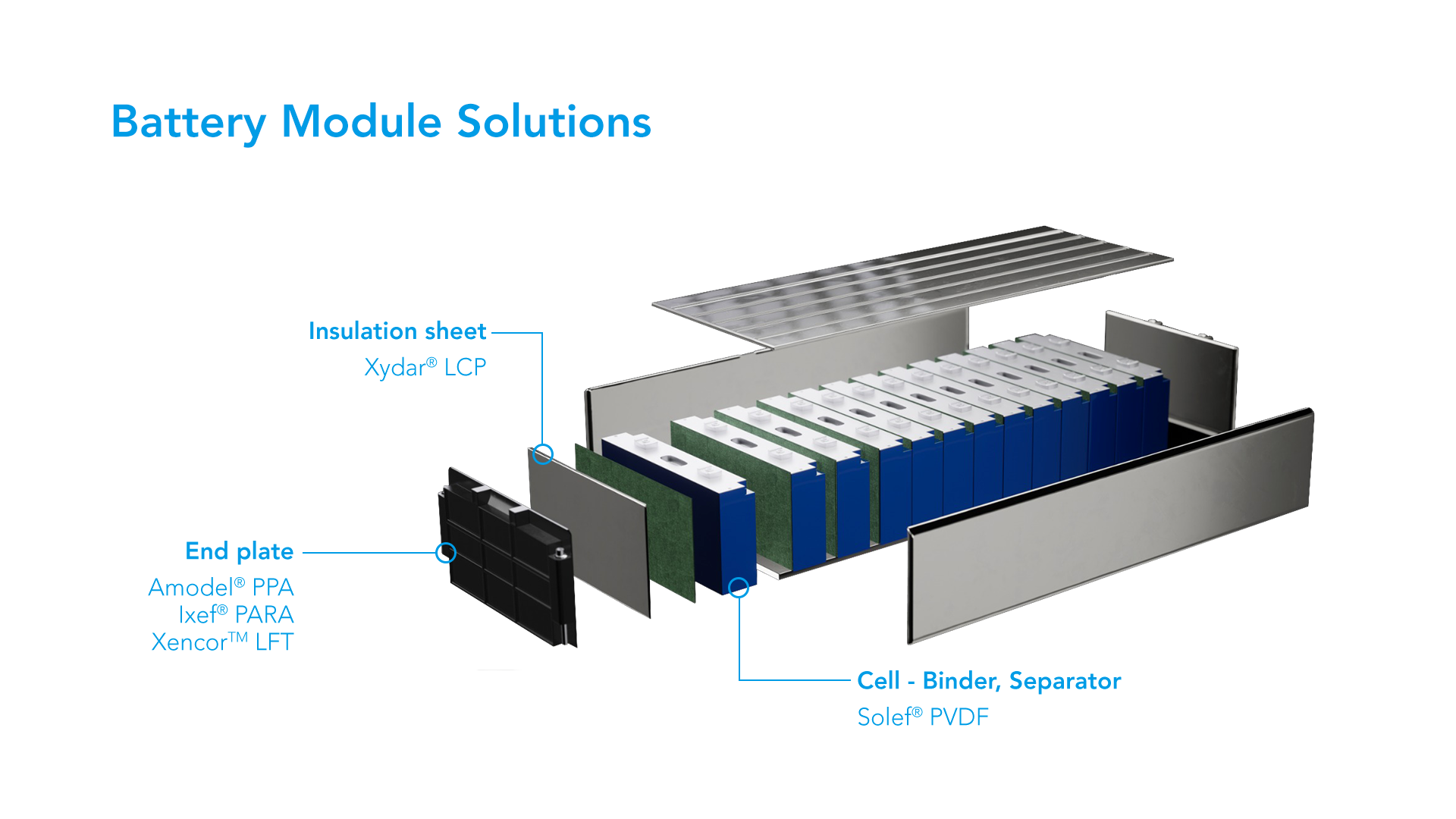

Additionally at Fakuma, Solvay (Stand B4 – 4213) is introducing its latest materials designed for thermal runaway protection in electric vehicle batteries. Called Xencor™ XTreme, it’s a new family of long-glass-fiber PPA resins and is designed for battery components such as overmolded busbars, module end plates and fixtures.

“We have multiple products that were designed for thermal runaway protection, including Xencor XTreme PPA and Xydar G-330 HH,” noted Batailley. “Both were designed to withstand temperatures ranging from 300 to 1,000 deg C for over a broad range of times. Xencor XTreme PPA is the highest rated for the PPA family and Xydar G-330 HH is the highest rated for liquid crystal polymers.”

PPA is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline and can be used in injection molding.

Promoting circularity

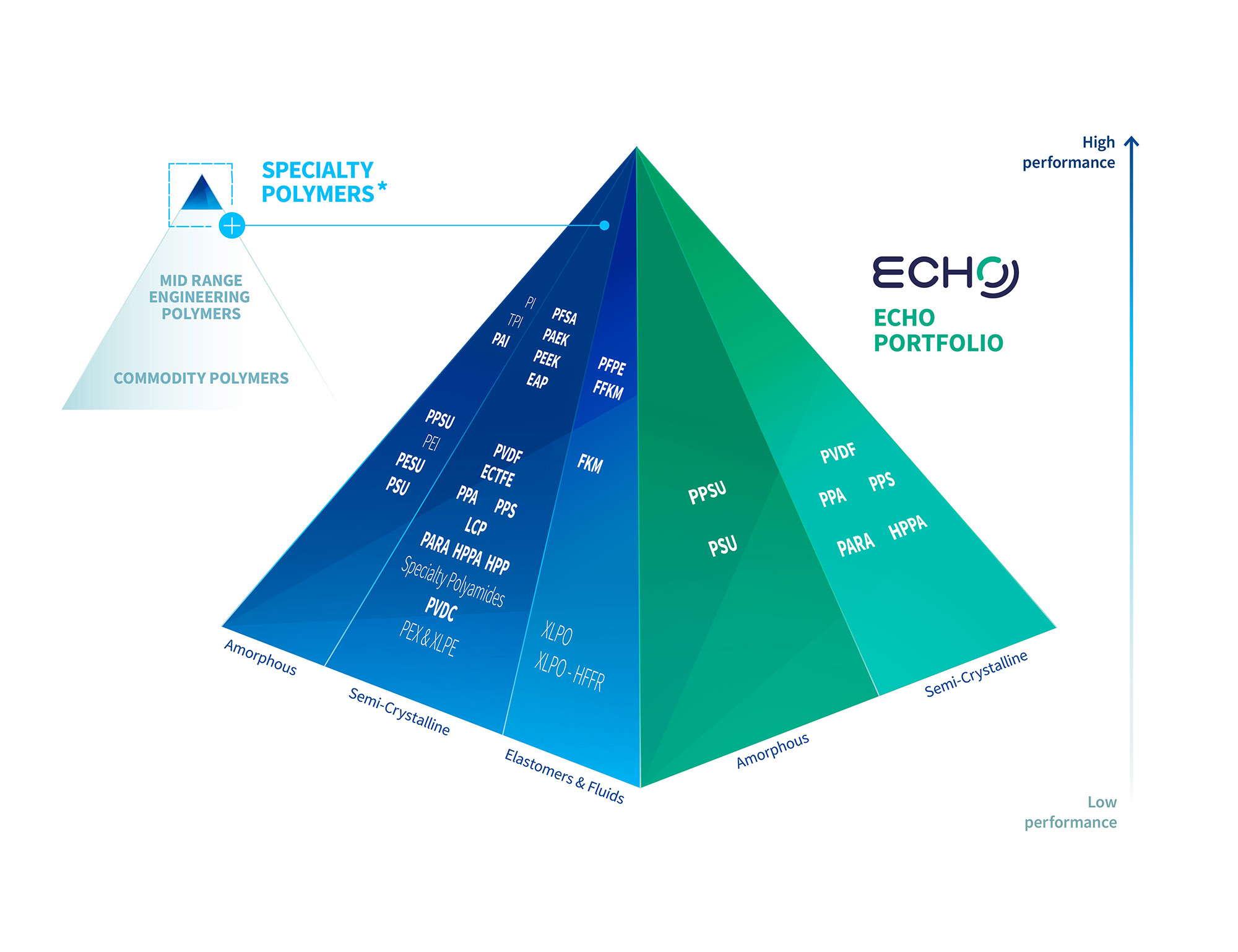

Solvay also will use its platform at Fakuma in Friedrichshafen to highlight its ongoing sustainability efforts. The company will introduce its new Echo brand, under which it is grouping its diverse range of circular materials.

Its new Echo portfolio groups together those materials aimed at advancing circularity and carbon neutrality. Courtesy of Solvay

“Our Echo portfolio brings together all our sustainable solutions, engineered with bio-based, recycled and mass-balance-certified raw materials, without compromising on performance,” said Ysée Génot, e-mobility and sustainability marketing manager.

Designed to reflect Solvay’s commitment toward a carbon-neutral future, “our Echo technologies provide high quality, sustainable alternatives to reduce the environmental impact of the industry, with performance equivalent to their original counterparts,” she added.

Brian Baleno, head of automotive marketing for Solvay Materials, noted that the company produces the two new Ryton PPS grades with 100 percent renewable electricity. Génot said that most of Solvay’s resins manufactured in the U.S. are based on 100 percent renewable (RE) electricity. “The ambition is to move all our sites to 100 percent RE and, in the future, to carbon neutrality.”

Gaining mass-balance certification

Separately, Solvay announced last month that it has obtained independent mass-balance certification under the widely recognized International Sustainability and Carbon Certification PLUS (ISCC PLUS) scheme of accreditation at two locations –– its PPS production at Borger, Texas, and its Ryton PPS Echo compounding at Kallo-Beveren, Belgium.

The firm says these products offer the same technical qualities as comparable virgin PPS resins, which eliminates the need for re-validation and makes these bio-circular PPS products “particularly attractive to manufacturers seeking a smooth and reliable transition to more sustainable and eco-responsible materials.”