No Pelletizing Needed for Injection Molding

Engel’s new two-stage process plasticizes recycled flake, increasing circularity and reducing CO2 emissions

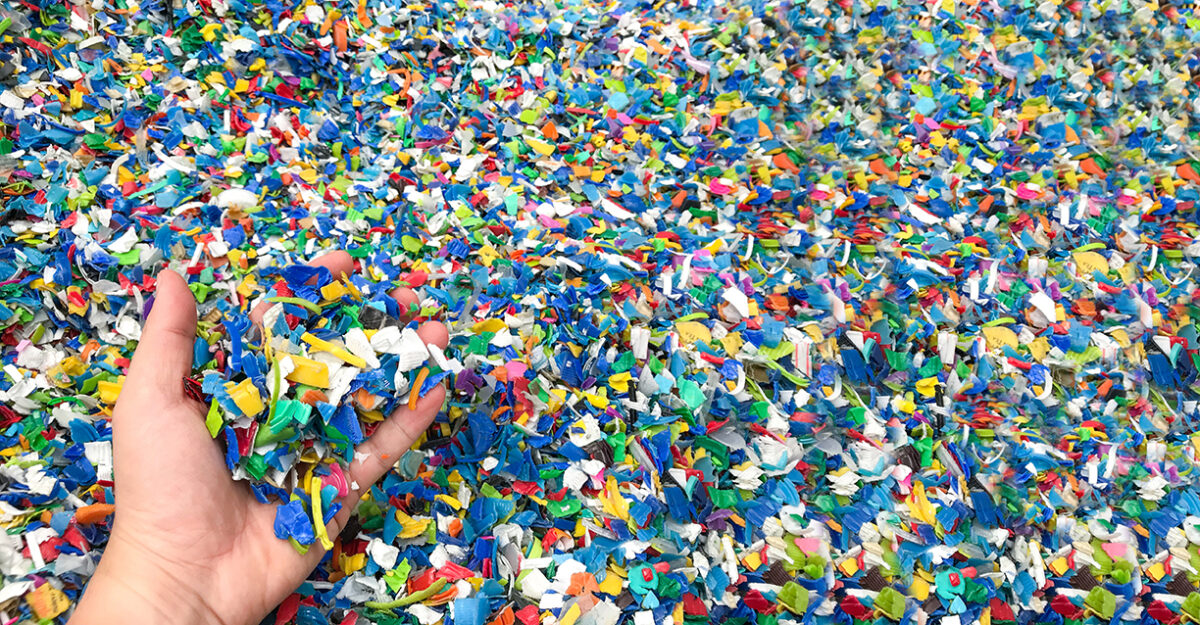

Injection machine maker Engel has developed a technology to streamline the use of recycled plastics with a two-stage molding unit that processes flake, eliminating the need to pelletize scrap, whether generated in-house or from post-consumer recycled (PCR) material.

The process, unveiled at a recent e-symposium by Engel, improves the circularity of plastics and helps lower carbon emissions by molders, since the elimination of pelletizing reduces the amount of energy expended during operations. Energy reductions in the form of heating and cooling operations when material is pelletized additionally generate cost savings for molders and speed process cycles.

The technique is called two-stage process technology, says Günther Hammer, vice president of plasticizing systems and recycling at Engel headquarters in Schwertberg, Austria (U.S. office is in York, Pa.).

In-line Melt and Molding

The flake is first conveyed to a plasticizing screw and barrel, which are mounted in-line with an injection unit. After plasticizing, melt transfers to the injection unit. Both barrels are connected via a melting line and separated by a shutoff device. “Depending on the final product and process, the whole system either operates in a start-stop mode or melt buffering can be realized between both units to ensure continuous plasticizing,” says Hammer, in response to emailed questions about the process.

“Plasticizing and injection are two independent successive process steps that are very well tuned with each other,” he adds. To assure the quality of PCR prior to molding, a melt filter and degassing unit can be integrated between the two barrels. Engel officials stated at the e-symposium that keeping the plasticizing and injection processes separate significantly increases process efficiency.

The injection unit can be equipped with either a conventional screw or a specially designed piston. Hammer says the screw generates shots of 2 to 45 kg (4.4 to 99 pounds), while the piston is for shot weights ranging from 30 to 160 kg (66 to 352 pounds). Injection screw diameters range from 70 to 260 mm. The piston diameters are between 170 and 320 mm. When using a screw for injection, processors generate the same injection pressures as with standard injection molding. With the piston, injection pressures reach as high as 1,300 bar.

The piston incorporates a design developed by Engel to eliminate what company officials call the “typical disadvantages of piston injection units when changing materials.” To achieve this, the tip is rheologically optimized to promote uniform flushing around the piston, enabling fast material and color changes.

With the piston’s large-part capabilities, the two-stage process technology can be used to mold thickwall parts such as containers, pallets and large fittings.

Importantly, processors do not need special molds for the technology no matter which system they use, injection screw or piston. “The goal is to use the molds designed for standard injection molding processes,” Hammer says.

Broad Material Capabilities

There appear to be no limitations regarding the types of recycled materials that the system processes. “In terms of purity, we are guided by the usual application limits of melt filters available on the market,” Hammer explains. “At present, customers process polyolefins, polystyrene and engineering plastics. The machine concept, however, also covers polyethylene terephthalate, polyamides and other resins.” Engel does require a sample of the recycled material prior to designing a system.

The size of the flakes depends on the diameter of the plasticizing screw, says Hammer, who adds that flakes should be below 8 or 12 mm. “The length and diameter of the plasticizing screw are in the range of a typical extrusion line—approximately 36 L/D.”

There is no need for, or for that fact any restrictions on, additives and other materials for mixing with the flake. “Additives are not absolutely necessary, but colors, glass fibers, stabilizers, entraining agents and other additions are conceivable,” Hammer notes.

In terms of potential energy economies that processors achieve with the system, Hammer estimates that “the saving is about 400Wh/kg for high-density polyethylene, as an example.” Energy costs vary around the world, of course, but he notes: “We only need to heat the flakes up once and cool the melt down in the mold. Typical applications heat recycled material up, cool it down to get granules, which then can be used in a standard injection unit process where they have to be heated again and cooled down again.”

One likely benefit of the process is that it reduces the heat history of the recyclate that’s being molded, which could in turn improve part properties.

The technology is available globally, but Engel has not made it a standard feature on its injection machines. As noted, Engel examines the recycled materials molders want to process before custom designing systems and machines for them. “Machines are individually designed, by getting back to the building blocks of our existing portfolio,” Hammer advises. While a retrofit to existing Engel machines “is possible in principle, we will see whether the market requires this.”

Aspects of the two-stage process technology were developed with input from Johannes Kepler University of Linz, Austria, and the Competence Center CHASE GmbH in Linz, primarily to analyze different material streams and evaluate processability and needed melt filters. Competence Center CHASE (an acronym for Chemical Systems Engineering) is a joint venture between business, academia and government in Austria. Goals include research geared toward digital innovation and sustainability.