AI-Based Sensor Improves Productivity in Composites Manufacturing

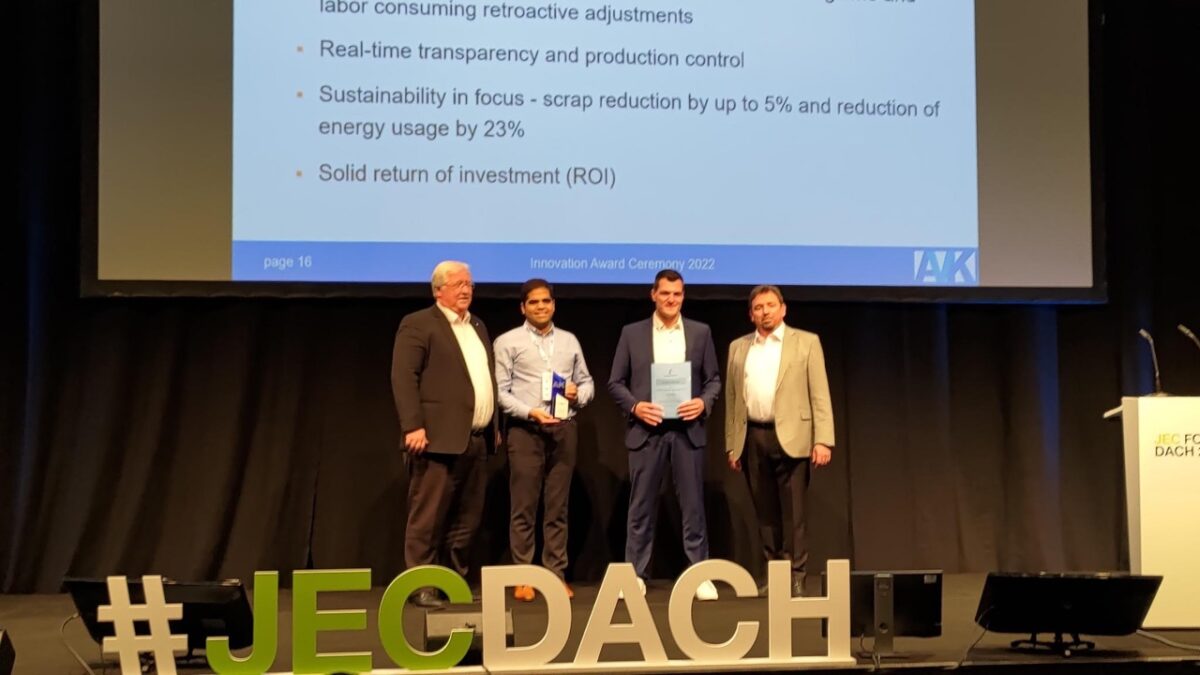

AVK (Federation of Reinforced Plastics) honored sensXPERT with this award for its AI-based Digital Mold sensor technology. Photos courtesy of sensXPERT

AVK, the Frankfurt, Germany-based Federation of Reinforced Plastics, named sensXPERT winner of its 2022 Innovation award for the Digital Mold process sensor system it developed. The company is part of Netzsch Process Intelligence GmbH, of Selb, Germany. (U.S. office is Netzsch Instruments North America, Burlington, Mass.)

Digital Mold is described by sensXPERT as using artificial intelligence (AI) in an intelligent manufacturing technology for composites that enhances productivity in real time. Developed for use primarily with thermosets in injection molding, compression molding, reaction injection molding, resin transfer molding, hot pressing and vacuum infusion, as well as autoclave curing, Digital Mold combines advanced machine learning with real-time mold and material science data.

Dielectric sensors characterize materials in sync with machine and mold operation to detect and control process factors for enhanced reliability. The sensors are in contact with the entire mold and gather data from within the material being processed, not just from its surface. The information is then combined with material science data so that an engineer can be notified if injection pressure or any other process parameter needs modification.

“We take over quality control for each part, in a non-destructive manner, during manufacturing, lowering the cost and effort required for post-process quality assurance,” says Dr. Alexander Chaloupka, founder and CTO of sensXPERT. “Our technology monitors how a material behaves during manufacturing, which allows us to react to deviations, whether from the material or from [an atmospheric] change such as a thunderstorm.”

“One of the big challenges in implementing AI is gathering the necessary data,” adds Chaloupka. “We collect the data with our sensors and combine it with kinetic data for the material, which serves as input for our machine learning models.”

Importantly, he remarks, “The real-time data feed the machine learning models, which helps retrain these models, effectively optimizing each machine.”

Every machine has its own machine learning model that calculates the quality parameters of materials in real time. This means that if a customer has 10 identical injection molding machines producing the same parts with the same material under the same conditions, the same model is initially applied to each machine. However, the models will then use data from each machine to make adjustments that keep the processes on individual machines optimal.

Thermosets in particular benefit from the sensXPERT technology since processing them depends on many parameters. “Thermosets can represent a big pain point,” Chaloupka notes. “Our customers sometimes don’t understand how these materials interact with storage or can be affected by [weather] changes or small temperature changes within the mold.”

With the process monitoring technology, efficiency is enhanced in several ways. Customers have, for example, been able to cut cycle times while reducing scrap. “In the thermoset market, we’ve been able to reduce process temperature by 5°C while showing the material behavior doesn’t change much,” Chaloupka says. “This reduces energy consumption and thus cost.”

The sensXPERT technology also combines simulation and real-time data to build a real-time simulation based on sensor data and infinite element analysis. This provides a detailed picture of what is happening in the mold as well as a big picture of the manufacturing process that together deliver increased transparency in processing.

Users of Digital Mold technology include the Airbus Research and Technology Composite Team. Aircraft engineers use the sensors and AI capabilities with various materials in different process scenarios. Crucial parameters such as the degree of curing and glass transition temperature are recorded in accordance with highly sensitive state-of-the-art laboratory measurements.

AVK honored the sensXPERT technology on Nov. 29, with the award in the category of “Processes and Procedures.” Chaloupka remarked then: “We will continue to work on making manufacturing processes more sustainable and efficient. This can only be achieved through a collaborative partner network, through which the knowledge that our customers need is digitalized and made available as a support tool.”