Sustainability Is Major Topic at SPE Additives and Color Conference

Experts gather in Brussels to discuss developments in additives, pigments, dyes and masterbatches

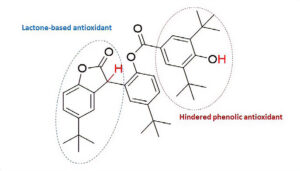

Palmarole discussed a new benzofuranone-based antioxidant with an additional hindered phenol at the conference. This stabilizer is formulated to aid in recycling without the environmental health and safety problems of previous EU versions. Courtesy of Roberto Todesco

At this year’s SPE Additives and Color Europe conference, industry executives from Europe and other parts of the world came together to talk about the latest in state-of-the-art additives, pigments, dyes and masterbatches. The meeting, held in Brussels March 8 to 10, provided an important connection point for the entire value chain, from raw material and equipment suppliers to OEMs.

In addition to sharing knowledge on a variety of relevant topics, the conference focused on several key themes including understanding OEMs’ expectations to better meet their growing needs, extending the life of plastics, conforming with new regulations, and improving recycling and sustainability.

“Durability and recyclability continue to be important in the field of polymers,” said Roberto Todesco, senior technical specialist for additives at RVT Consulting, in Basel, Switzerland, and a member of the SPE Additives and Colors Europe board for more than 20 years. “We hope that some of the recycling case studies at the meeting showed attendees that nothing is impossible and inspired them to try similar things in their company.”

A New Benzofuranone

Todesco consults for Switzerlandbased Palmarole, which presented a new benzofuranone-based antioxidant processing stabilizer that can aid in recycling. Benzofuranones were introduced in the 1990s as processing stabilizers for polyolefins. Although these stabilizers worked well, they were taken off the market after the discovery of significant environmental health and safety (EHS) concerns.

Palmarole’s new AO.LA.002 benzofuranonebased antioxidant has been thoroughly tested to show that it can be used without the EHS concerns of the former product. “This additive aids in recycling because it prevents the recycled polymer from further degrading when it goes through extrusion or injection molding,” he said. “It is good for all polyolefins and all kind of applications, but it is especially useful for processes taking place at higher temperatures than usual.”

Todesco also presented a seminar on how to reformulate stabilizers in polyolefin substrates. This has become an important topic due to problems with securing stabilizers, which have been going on for the past five years. “The problems got worse during the COVID pandemic and are still an issue because of logistics chain issues and shortages of raw materials,” he explained. “In addition, various stabilizers have been placed on the EU’s Substance of Very High Concern list, which, for most companies, means having to find a different additive to use.”

Todesco’s seminar walked participants through which stabilizers or combination of stabilizers can be exchanged for others, including alternatives for the most used phenolic antioxidants, phosphites, thioesters, UV absorbers and hindered amine light stabilizers. “If you wait until you can’t get or use a certain stabilizer to think about alternatives, then it’s too late,” he advised. “I want to help people be prepared.”

Long-Lasting Insecticide

Aimplas Plastics Technology Center developed masterbatches for long-lasting insecticide effects in plastics. Tests reportedly show that the masterbatches exhibit 100 percent insecticide performance after six months. Courtesy of Luis Roca/Aimplas

UV absorbers and hindered amine light stabilizers. “If you wait until you can’t get or use a certain stabilizer to think about alternatives, then it’s too late,” he advised. “I want to help people be prepared.”

Long-Lasting Insecticide

Luis Roca, compounding leader at the Aimplas Plastics Technology Center in Valencia, Spain, pointed out that plastics can have functions beyond aesthetics or mechanical performance. At the conference, he presented an example of this: masterbatches for long-lasting insecticide effects in plastic items.

“Through melt compounding, insecticides can be introduced into plastics in a way that allows them to be released after a period of time due to migration,” said Roca. “This can be applied to many injected or extruded products or films that interact with the pests that we want to control, which include flies, mosquitoes, ants and cockroaches.”

Because insecticides are volatile substances, they gradually migrate through the polymeric matrices until being released at the surface. He said that the main challenges in developing these masterbatches included figuring out how to avoid insecticide volatility and evaporation during compounding and how to increase the insect-killing effect of the insecticide.

“The insecticide’s effect depends on different factors such as the insecticide’s molecular weight, the polymer used, and the heat and moisture of the environment,” said Roca. “Our test showed 100 percent insecticide performance after six months. Most other approaches in the market involve coatings and have less lasting effect because the migration is faster.”

Recycling Black Packaging

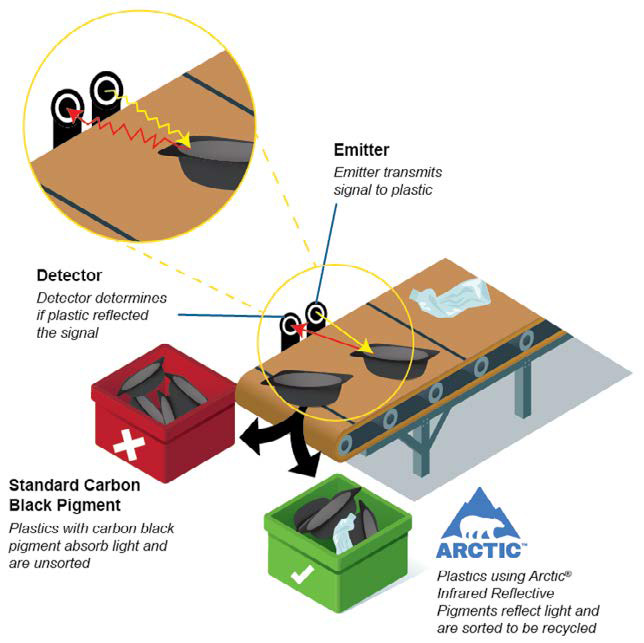

Mark Ryan, global market and product manager at Cincinnati-based Shepherd Color Co., discussed new pigments that improve sustainability by making black food packaging recyclable. Commonly used black pigments absorb near infrared (NIR) wavelengths, which prevents their classification by NIR-enabled automated sorting equipment. Shepherd offers a new line of pigments that are generically known as IR blacks under its Arctic Infrared Reflective Pigments brand, which do not absorb critical NIR wavelengths and thus allow black plastic packaging to be identified and sorted for recycling.

During his talk, Ryan discussed how the Arctic Infrared Reflective Pigments can be optimized by adding phthalocyanine green (PG7) to increase jetness, or blackness, while preserving NIR properties. He also talked about how compared to standard carbon blacks, these IR black pigments exhibit different absorption properties in visible and UV spectra that may be relevant for thinner packaging materials.

“Improving recyclability is a global issue. We applied [Shepherd Color Co.’s] 40 years of experience with IR-optimized pigments to this new application,” Ryan said.

The company has several other black pigments for FDA-approved food packaging. “For first-use food containers, our Black 10F925 is the blackest black in the market,” he said. “For coloring recycled material, our Black 10F951 has the highest tint strength and lowest use rate to overcome and standardize to a dark color without compromising further recyclability of materials. When coloring recycled material, the tint strength and low use ratio are more important than the mass-tone color.”

Shepherd Color Co. also has a new cobalt blue pigment called Maximum Chromaticity Blue 20G599. “It is the most chromatic blue that we have ever developed or seen,” Ryan said. “It pushes the red and blue values to give a brilliant shade of blue. This product shows that even older chemistries, when properly designed and produced, can be used to expand the durable color envelope.”

Shepherd Color’s Arctic Infrared Reflective Pigments don’t absorb NIR wavelengths and so allow plastics to be identified and sorted for recycling. Courtesy of Shepherd Color Co.